Milling drilling machines

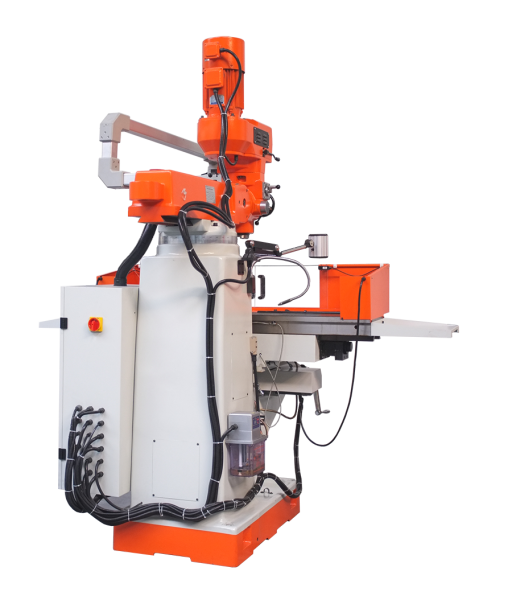

EUROMET FW33 NC milling and drilling machine

76 600,00 zł net

No rating

12 months of warranty

Contact with a trader:

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

The EUROMET FW33 NC milling and drilling machine is a machine with a swivel-rotary head (in two axes), of small dimensions, with a wide possibility of processing. This model has built-in NC functions that enable milling in several variants, which makes it similar to CNC milling machines.

Quantity

Add to cart

The EUROMET FW33 NC milling and drilling machine is a machine with a swivel-rotary head (in two axes), of small dimensions, with a wide possibility of processing. This model has built-in NC functions that enable milling in several variants, which makes it similar to CNC milling machines. The functions of the machine allow for automatic milling in the following modules:

- Milling around a square / rectangle

- Milling around the circumference of a circle / cylinder

- Drilling multiple holes in a linear pattern

- Drilling multiple holes in a circle

DEVICE FEATURES:

Manual feed control:

After setting the start and end points of the XY axis movement, the table moves automatically at the appropriate speed. Speed range from 0 ~ 1500mm / min.

Automatic XY axis navigation:

The machine can be operated in the same way as a conventional vertical milling machine. The feed of all axes can be driven by a mechanical handwheel or by MPG, which greatly simplifies and speeds up the work.

Face milling function:

It is enough to enter a few key cutting parameters on the control panel and the machine automatically performs milling on the plane.

Peripheral cutting function (milling external and internal rectangles)

Enter the length and width of the outer or inner rectangular part, then the machine automatically cuts around or inside the selected shape.

Cylinder milling function (cutting outer cylinders and drilling holes)

Enter the radius of the cylinder or hole and tools, the machine will automatically cut the desired shape.

Linear multi-hole drilling:

After entering the number of holes, the distance and making the first hole manually, the worktable will automatically move to the next holes and then drill them one by one.

Multi-hole circular drilling:

After entering the number of holes, the distance and making the first hole manually, the worktable will automatically move to the next holes along the circle line, and then drill the holes one by one.

Standard equipment:

- X, Y axes driven by a servo motor

- Color touch screen

- PLC control

- Control panel on a movable arm

- CE declaration

- Manual in English

- Handling tools

- NC control (HMI)

| Technical data | Unit | Value |

|---|---|---|

| Table dimensions (length) | [mm] | 1500 |

| Table dimensions (width) | [mm] | 330 |

| X axis feed range | [mm] | 1000 |

| Y axis feed range | [mm] | 380 |

| Z axis feed range | [mm] | 460 |

| Spindle speed range | [rpm/min] | 0 - 3600 |

| Spindle taper | [-] | ISO No. 40 |

| T-slots (No. x width x spacing) | [mm] | 5x16 |

| Feed rate (X / Y / Z) | [mm/min] | 0-1500/0-1500/460 |

| Distance between the vertical spindle and the center of the table | [mm] | 0-450 |

| Left and right slope | [°] | +/- 45 |

| Rotate the head left and right | [°] | +/- 95 |

| Spindle extension | [mm/rpm] | 0,04/0,08/0,15 |

| Device dimensions | [mm] | 1800x2020x2200 |

| Machine weight | [kg] | 2200 |

Recommended

Milling drilling machines

54 228,24 zł

No rating

Milling drilling machines

33 825,00 zł

No rating

Milling drilling machines

82 884,78 zł

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.