Didactic milling machines

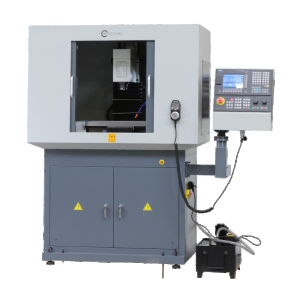

COR Educational Station

187 100,00 zł net

No rating

12 months of warranty

Contact with a trader:

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

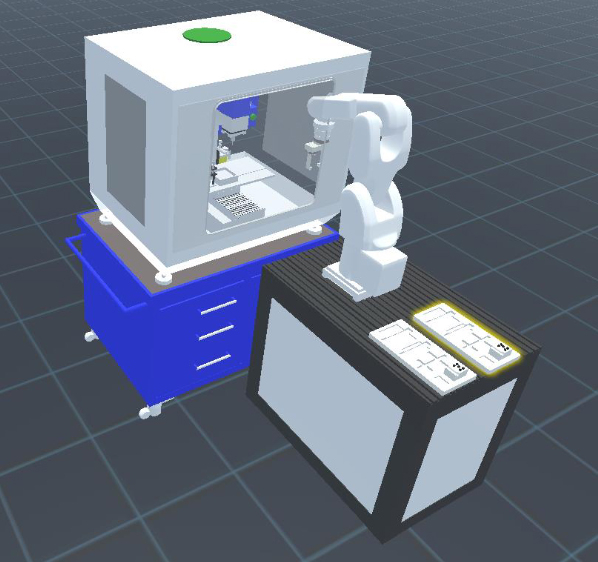

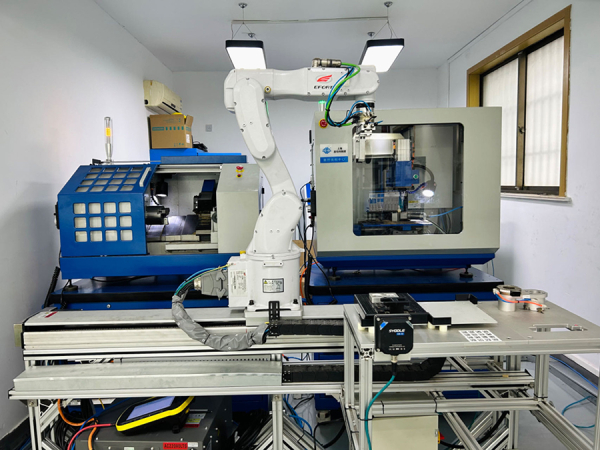

CNC machining center and 6-axis robot with pneumatic chuck by Effort.

Quantity

Add to cart

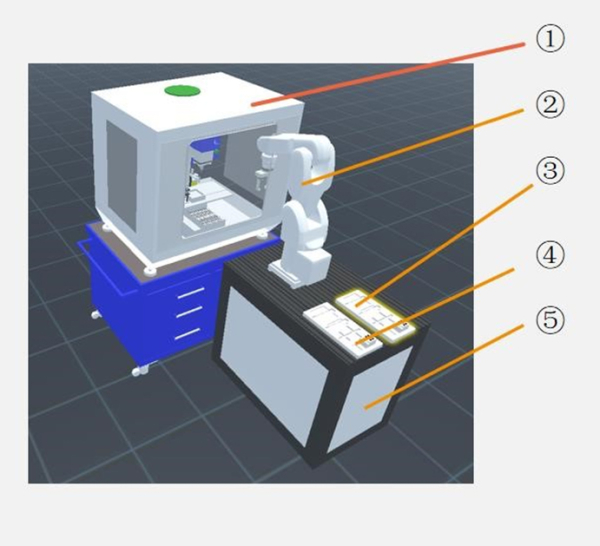

① CNC machining center SKOLAR iX1 with pneumatic door, single-axis pneumatic vice and I/O communication port.

② 6-axis robot with pneumatic chuck (recommended Effort brand).

③ Raw parts library, 6 stations, made of aluminum material, adapted to the shape of the part.

④ Finished parts library, 6 stations, made of aluminum material, adapted to the shape of the part.

⑤ The robot base is made of aluminum alloy and sheet metal, with 4 wheels at the bottom. On the top of the base, there is a robot, raw parts library, finished parts library. And the control component is installed inside the base.

Knowledge and skills that can be acquired:

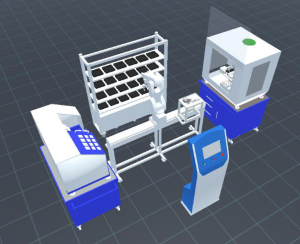

The COR machining center loading and unloading workstation, the machine tool module and the robot module have movable wheels at the bottom. The I/O communication port between the machine tool and the robot is installed outside the machine housing. The separation and connection of the workstation are fast and convenient.

- The COR workstation can enable independent training and operation of the CNC machine tool and the robot, as well as CNC machine tool machining programming and robot control programming.

- Possibility of learning the automatic loading and unloading function and programming training of the workstation.

- Possibility of learning the operation of the robot parts between two part libraries.

- Possibility of learning the communication and exchange of information between the CNC machine tool and the robot.

- Possibility of learning and training in the robot programming software in offline mode.

Recommended

Didactic milling machines

94 710,00 zł

No rating

Didactic milling machines

560 142,00 zł

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.