Machine categories

Band saws

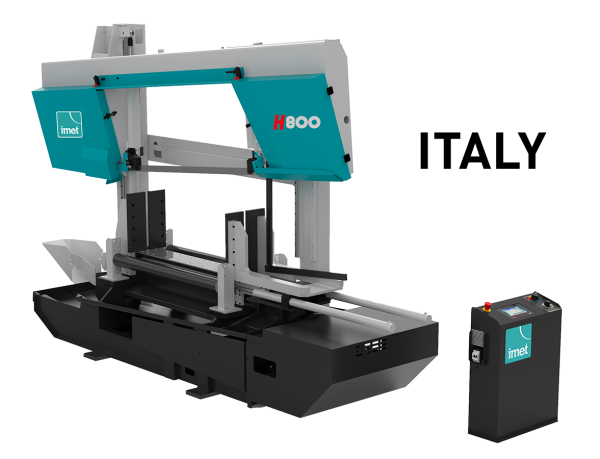

IMET H 800 column semi-automatic cutting machine

268 249,00 zł net

No rating

12 months of warranty

Contact with a trader:

Krzysztof Penkowski

E-mail: krzysztof.penkowski@eurometal.com.pl

Telefon: 603 400 333

Krzysztof Penkowski

E-mail: krzysztof.penkowski@eurometal.com.pl

Telefon: 603 400 333

The IMET H 800 two-column semi-automatic cutter is a band saw for straight cutting (90°), which ensures high working efficiency with reliable cutting quality and an optimized cutting process thanks to the blade inclined at an angle of 5°, which facilitates the penetration of the material even in the case of the largest sizes. The machine is suitable for bars, pipes, solid materials and carpentry work.

Quantity

Add to cart

H series band saws are equipped with a wide work plate that fully supports the material, allowing for stable and reliable cutting.

H 800 saws are electrically welded from rigid tubular steel and of high thickness, which helps reduce vibration when cutting even the largest diameters. The massive design also avoids binding or slowing down the cutting speed.

Semi-automatic cutters are equipped with a mobile control panel and a 10-inch touch screen with a simple and intuitive interface that gives the user full control and the ability to configure and modify all settings and functionalities of the machine.

The cutting process is optimized with a 5° inclined blade that facilitates material penetration, reducing belt stress, helping to extend blade life and improving cutting performance even on solid materials and large diameters and cross-sections.

IMET band saws are characterized by high blade tension (2000 kg/cm2 in the H 800 model), which increases the efficiency of the machine for any type of material and cross-section.

The H 800 and H 1200 recognize the starting cutting point thanks to a magnetic strip with an encoder for material reading: the operator must set the material size on the control panel, the machine starts automatically quickly lowering the saw frame to the set value. This process allows for a faster and easier approach to the material, helping to save time.

The operator can choose from a variety of final cutting options: lifting the saw frame when the saw blade is not running, with the saw blade running and finishing cycle without moving the bail.

Registered blade guides in metal washers and bearings. The movable blade guide is automatically held next to the cutting area.

The machine is equipped with a motorized cleaning brush with nylon teeth to remove residue in the cutting area and on the blade.

The H 800 is equipped with a full-stroke hydraulic horizontal vice, thanks to which the material is perfectly locked and ready for cutting.

Device features:

- Columnar structure

- Maximum cutting diameter: ø 680 mm

- Smooth regulation of belt speed

- Hydraulic unit

- Hydraulic vices

- Powered belt cleaning brush

- Mobile control panel

- The tape is inclined at an angle of 6 degrees to the material being cut

Standard equipment:

- Cooling system

- Bimetallic tape – 1 piece in the machine

- User manual in English

- CE certificate

Optional equipment (additionally paid):

- Roller feeders

- Package cutting clamps

- Measure with bumper

- Connector

- Oil mist lubrication system (micronizer)

- Strain gauge for precise setting of belt tension

| Technical data | Unit | Value |

|---|---|---|

| The width of the cutting band | [mm] | 41 |

| Vise opening width | [mm] | 820 |

| The dimensions of the cutting band | [mm] | 7260x41x1.3 |

| Cutting band speed | [m/min] | 15-100 |

| Cutting band motor power | [kW] | 5.5 |

| Working height | [mm] | 800 |

| Hydraulic reservoir capacity | [l] | 20 |

| Dimensions | [mm] | 1550x3600x2700 |

| Weight | [kg] | 3100 |

Recommended

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.