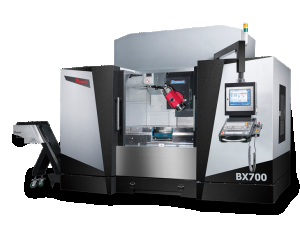

CNC machining center

PINNACLE LV116 CNC machining center (linear guides)

400 176,00 zł net

No rating

12 months of warranty

Contact with a trader:

Krzysztof Penkowski

E-mail: krzysztof.penkowski@eurometal.com.pl

Telefon: 603 400 333

Krzysztof Penkowski

E-mail: krzysztof.penkowski@eurometal.com.pl

Telefon: 603 400 333

The LV series (PINNACLE LV116 CNC machining center) is a 3-axis vertical machining center with a cross table for X/Y movement and a headstock for vertical Z movement. Linear roller guides in all axes ensure high dynamics and high positioning accuracy. LV series vertical machining centers can be equipped with a CNC rotary table, transforming them into 4- or even 5-axis machines.

The PINNACLE LV116 CNC machining center from the LV series is a 3-axis vertical machining center with a cross table capable of X/Y movement and a headstock capable of vertical Z movement. Linear roller guides on all axes ensure high dynamics and high positioning accuracy. LV series vertical machining centers can be equipped with a CNC rotary table, transforming them into 4- or even 5-axis machines.

High feed rates of up to 36 m/min and high rotational speeds of up to 15,000 rpm enable high-performance machining. Thanks to a wide range of optional accessories, the machines are suitable for both mold making and mass production. The LV series' X-axis travel ranges from 850 mm to 1400 mm. The machines are available with all the most popular control systems available on the market, including Fanuc, Sinumerik, and Heidenhain.

The LV series is identical to the SV series, except that the LV machines are equipped with linear guides.

Standard equipment:

- Spindle air blast

- Workpiece air blast

- Chip flushing

- Telescopic guide guards

- Automatic lubrication system

- Work light

- Machine status indicator

- Cooling system

- Compressed air and coolant gun

- MPG handwheel

- Electrical cabinet cooling

- Rigid tapping

- Chip conveyor

- English user manual

- CE declaration of conformity

Additional equipment:

- Control system: FANUC 0i-MD/ 31i-MB, SIEMENS 828D/ 840D, FAGOR 8055i Plus, - MITSUBISHI M70/ M720/ M730 - HEIDENHAIN iTNC530/ TNC620

- Tool magazine types: Carousel, Drum, Chain

- Through-spindle cooling

- Coolant tank with paper filter

- Tilting rotary table (4th/5th axis controlled)

- Rotary table (4th axis controlled)

| Technical data | Unit | Value |

|---|---|---|

| Table surface (length) | [mm] | 1300 |

| Table surface (width) | [mm] | 610 |

| X axis travel | [mm] | 1140 |

| Y axis travel | [mm] | 610 |

| Z axis travel | [mm] | 610 |

| Table load | [kg] | 850 |

| T-slots (W x Pitch mm x °) | [-] | 18 x 125 x 5 |

| Distance between the spindle and the table | [mm] | 120-730 |

| Spindle taper | [-] | ISO40 |

| Spindle speed (direct drive) | [rpm/min] | 0 - 15000 |

| Spindle speed (toothed belt drive) | [rpm/min] | 60 - 8000 |

| Spindle speed (gear drive) | [rpm/min] | bieg niski: 40-2000, bieg wysoki: 2001-8000 |

| FANUC servo motor (continuous / 30min KW) | [-] | 11/15 (β12/7000i) |

| Distance from the spindle axis to the column surface | [mm] | 675 |

| Spindle motor power | [kW] | 7,5 / 11 |

| Rapid feed (X / Y / Z) | [m/min] | 30 / 30 / 24 |

| Working feed (X / Y / Z) | [m/min] | 10000 |

| The power of FANUC feed servo motors | [kW] | β22/3000is 3.0 (α12i/3000i 3.0) |

| Tool magazine type | [-] | karuzelowy/bębnowy/łańcuchowy |

| Tool magazine capacity | [pcs] | 24 |

| Tool diameter | [mm] | 90 |

| Tool length | [mm] | 250 |

| Tool weight | [kg] | 8 |

| Electrical connection | [kVA] | 20 |

| Coolant tank capacity | [l] | 200 |

| Dimensions (LxWxH) | [mm] | 2950 x 3100 x 2230 |

| Weight | [kg] | 6500 |

Media

16.12.2021

Centrum frezarskie cnc PINNACLE LV116

Recommended

CNC machining center

No rating

CNC machining center

Priced individually

No rating

CNC machining center

Priced individually

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.