CNC machining center

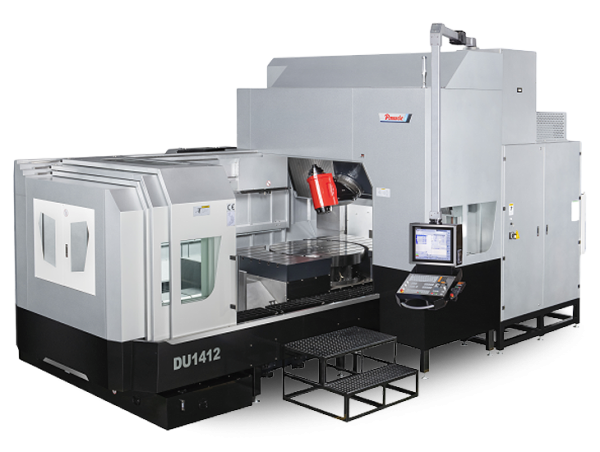

PINNACLE DU1422 machining center

Priced individually

No rating

12 months of warranty

Contact with a trader:

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

The PINNACLE DU1422 machining center enables heavy-duty milling operations. The Pinnacle DU series is designed to provide high-performance, accurate machining of complex parts with a single workpiece setup. This means reduced setup time and increased machine accuracy.

The PINNACLE DU1422 machining center enables heavy-duty milling operations. The Pinnacle DU series is designed to provide high-performance, accurate machining of complex parts with a single workpiece setup. This means reduced setup time and increased machine accuracy.

Main features of the machine:

- Movable beam structure

- High-speed 15,000 rpm spindle

- 3-axis linear scales

- Completely enclosed machining space

High rigidity and high precision construction in the DU series

- The robust design ensures excellent rigidity and stability.

- High-quality Meehanite cast iron (FC30) is used.

- The beam can move vertically thanks to ball screws placed symmetrically on both sides.

- The Z axis is equipped with two linear scales to ensure synchronization between the two ball screws.

- Z-axis movement is balanced by two hydraulic cylinders combined with a chain mechanism to reduce hydraulic costs and energy consumption.

- Heavy-duty roller linear guides on 3 axes.

Standard equipment:

- Heidenhain TNC640 controller

- HR510 handwheel

- 24-station drum tool changer

- Thermally stabilized spindle with oil circulation

- Air-through tool cooling

- 3-axis feed ball screws cooled through internal channels

- Full machining area enclosure

- 3-axis linear scales

- Screw-type chip conveyor

- Chain-type chip conveyor

- Hydraulic counterbalance system on the Z axis

- Air-conditioned electrical cabinet

- Automatic lubrication system

- Cooling system

- Compressed air gun

- Coolant gun

- Work light

- Operation status light

- Set of maintenance tools

- Leveling screws and feet

| Technical data | Unit | Value |

|---|---|---|

| Table surface (length) | [mm] | 2200 |

| Table surface (width) | [mm] | 1200 |

| X axis travel | [mm] | 2200 |

| Y axis travel | [mm] | 1400 |

| Z axis travel | [mm] | 600 |

| Table load | [kg] | 5000 |

| T-slots (W x Pitch mm x °) | [-] | 22x150x7 |

| Spindle taper | [-] | ISO 50 |

| Spindle speed | [rpm/min] | 0 - 8000 |

| Distance from the spindle axis to the column surface | [mm] | 764 |

| Spindle motor power | [kW] | 15/18.5 |

| Rapid feed (X / Y / Z) | [m/min] | 20/20/20 |

| Working feed (X / Y / Z) | [m/min] | 10000 |

| Tool magazine type | [-] | bębnowy |

| Tool magazine capacity | [pcs] | 24/32(60) |

| Tool diameter | [mm] | 125/250 |

| Tool length | [mm] | 400 |

| Tool weight | [kg] | 25 |

| Rotary table type | [-] | wbudowany |

| Rotary table diameter | [mm] | 1200 |

| The diameter of the hole in the turntable | [mm] | 50H7 |

| Rotation speed of the turntable | [rpm/min] | 600 |

| Load on turntable | [kg] | 3000 |

| Distance between the spindle and the table (head vertical) | [mm] | 130 - 1630 |

| Dokładność pozycjonowania osi A/C | [art-sec] | 0.005, - |

| Accuracy of A / C axis re-positioning | [art-sec] | 0.003, - |

Recommended

CNC machining center

784 740,00 zł

No rating

CNC machining center

Priced individually

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.