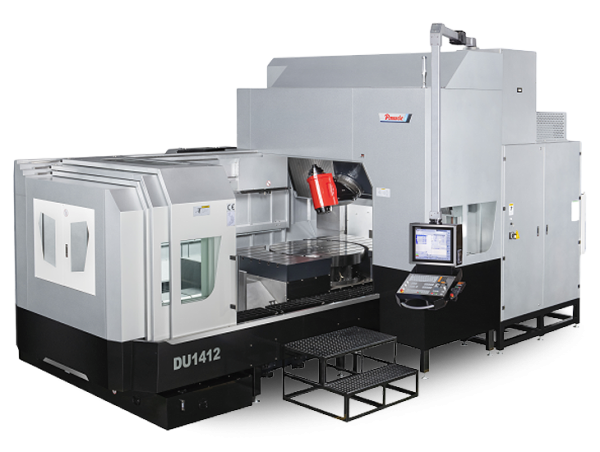

CNC machining center

PINNACLE DU1412 5-axis machining center

Priced individually

No rating

Contact with a trader:

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

The PINNACLE DU1412 5-axis machining center offers both heavy-duty milling and turning operations. The Pinnacle DU series is designed to provide high-performance, high-precision machining of complex parts with a single setup. This means reduced setup time and increased machine accuracy.

The PINNACLE DU1412 5-axis machining center offers both heavy-duty milling and turning operations. The Pinnacle DU series is designed to provide high-performance, high-precision machining of complex parts with a single setup. This means reduced setup time and increased machine accuracy.

Main features of the machine:

- Movable beam structure

- 45° rotatable spindle head ensures high-precision 5-axis machining

- High-speed 15,000 rpm spindle

- Rotary table supported by a hydrostatic bearing system to reduce vibration and increase rotational smoothness and machining accuracy

- A and C axes equipped with a rotary encoder for accurate orientation

- Direct drive on the A and C axes

- 3-axis linear scales

- DCM anti-collision software included as standard

- Completely enclosed machining space

- Turning possible thanks to a unique clutch mounting method at the spindle end

High rigidity and high precision construction in the DU series

- The robust design ensures excellent rigidity and stability.

- High-quality Meehanite cast iron (FC30) is used.

- The beam can move vertically thanks to ball screws placed symmetrically on both sides.

- The Z axis is equipped with two linear scales to ensure synchronization between the two ball screws.

- Z-axis movement is balanced by two hydraulic cylinders combined with a chain mechanism to reduce hydraulic costs and energy consumption.

- Heavy-duty roller linear guides on 3 axes.

45° ROTARY SPINDLE HEAD

The PINNACLE DU1412 5-axis machining center features a 45° swivel spindle head. Direct drive enables high speeds, rapid acceleration/deceleration, and optimal dynamic response, contributing to increased machining efficiency.

ROTARY TABLE SUPPORTED BY A HYDROSTATIC BEARING SYSTEM

- The rotary table (C-axis) is integrated into the rectangular table with T-slots, allowing it to accommodate larger workpieces.

- The rotary table is supported by a hydrostatic bearing system, allowing for high rotational speeds of up to 600 rpm, with a turning function.

- The C-axis is directly driven by a high-rigidity motor with a minimum indexing accuracy of 0.001°.

Standard equipment:

- Heidenhain TNC640 controller

- HR510 handwheel

- Kinematic software

- DCM anti-collision software

- 30-station drum tool changer

- Thermally stabilized spindle with oil circulation

- Air-through tool cooling

- 3-axis feed ball screws cooled through internal channels

- Full machining area enclosure

- 3-axis linear scales

- A-axis rotary encoder

- C-axis rotary encoder

- Screw-type chip conveyor

- Chain-type chip conveyor

- Hydraulic counterweight system on the Z axis

- Air-conditioned electrical cabinet

- Automatic lubrication system

- Cooling system

- Compressed air gun

- Coolant gun

- Work light

- Operation status light

- Set of maintenance tools

- Leveling screws and feet

| Technical data | Unit | Value |

|---|---|---|

| Table surface (length) | [mm] | 2200 |

| Table surface (width) | [mm] | 1200 |

| X axis travel | [mm] | 2200 |

| Y axis travel | [mm] | 1400 |

| Z axis travel | [mm] | 900 |

| Table load | [kg] | 5000 |

| T-slots (W x Pitch mm x °) | [-] | 22x150x7 |

| Spindle taper | [-] | HSK T63 |

| Spindle speed | [rpm/min] | 0 - 15000 |

| Distance from the spindle axis to the column surface | [mm] | 1000 |

| Spindle motor power | [kW] | 19/23 |

| The inclination of the electro-spindle head | [°] | -30~+180 |

| Head rotation speed | [rpm/min] | 50 |

| Rapid feed (X / Y / Z) | [m/min] | 20/20/20 |

| Working feed (X / Y / Z) | [m/min] | 10000 |

| Tool magazine type | [-] | bębnowy |

| Tool magazine capacity | [pcs] | 30(60)/40(80) |

| Tool diameter | [mm] | 75/150 |

| Tool length | [mm] | 300 |

| Tool weight | [kg] | 8 |

| Rotary table type | [-] | wbudowany |

| Rotary table diameter | [mm] | 1200 |

| The diameter of the hole in the turntable | [mm] | 50H7 |

| Rotation speed of the turntable | [rpm/min] | 600 |

| Load on turntable | [kg] | 3000 |

| Distance between the spindle and the table (head vertical) | [mm] | 150 - 1050 |

| Spindle distance from the table (head horizontally) | [mm] | 150 - 950 |

| Table indexing resolution | [-] | 0.001 |

| Dokładność pozycjonowania osi A/C | [art-sec] | 0.005, 10"/10" |

| Accuracy of A / C axis re-positioning | [art-sec] | 0.003, 8"/4" |

Recommended

CNC machining center

Priced individually

No rating

CNC machining center

Priced individually

No rating

CNC machining center

Priced individually

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.