Machine categories

Circular saws

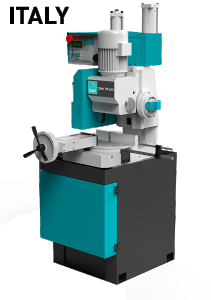

SOCO SA-78NCE circular saw + MB6 hopper

Priced individually

No rating

Contact with a trader:

Krzysztof Penkowski

E-mail: krzysztof.penkowski@eurometal.com.pl

Telefon: 603 400 333

Krzysztof Penkowski

E-mail: krzysztof.penkowski@eurometal.com.pl

Telefon: 603 400 333

SOCO SA-78NCE + MB6 circular saw (3m cutting length) with a brand new feeder. Automatic machine with the function of cutting - deburring / tube end termination - length measurement - laying

SOCO SA-78NCE + MB6 circular saw (3m cutting length) with a brand new feeder. Automatic machine with the function of cutting - deburring / tube end termination - length measurement - laying

Characteristics:

- a machine designed for the automotive industry and more

- the ability to cut high-strength details (up to 120kg/cm2)

- high speed: average cycle time is 4.5 seconds for most materials

- as standard, the machine is equipped with a 6.5 m feeder with a magazine (MB6), optionally 8.5 m (MB8 and 12.5 m (MB12)

- automatic separation of the first and last cut from the correct parts

- first and last section below 25 mm

- quick-change disc change system

- safety guards

- 1 or 2 digital readout stops, optionally available NC stops

- available two versions of the machine with a feeder on the left and right side

- max cutting diameter 76mm

- max cutting length 2 / 3 / 4.5 m depending on the model

- feeding and cutting by servo motors.

- i2 control with a touch screen and graphics, and automatic selection of cutting parameters.

- a unique disc mounting system and a system for eliminating backlash in the toothed gear

- possibility to connect deburrer (BDB-70), finisher (DEF-FA/76-V), measuring device (LM-300), stacker (STK-3000)

- possibility of cutting with TCT and HSS discs

- possibility of cutting pipes, square and rectangular profiles and rollers

- performance: profile 50x30 t=1.2, L=366, material with a tensile strength of 100Kg/cm2

- disc SOCO TCT model HTTM Ø280x120z)

- cutting time 4.99 sec

- cycle time 7.19 s

- blade capacity 10500 cuts

| Technical parameters | SA-78NCE | SA-78 NC + BDB 70 | |

|---|---|---|---|

| Cutting dimensions [mm] | Tube | 10-80 | 12.5~76 |

| Square profile | 10x10~70x70 | 12.5x12x5~70x70 | |

| Rectangular profile | 15x10~80x70 | 15x10~80x70 | |

| Roller | 12-30 | - | |

| Minimum cut length [mm] | 50 | 300 | |

| Maximum cutting length [mm] | 2000/3000/4500 | 2000/3000 | |

| Adjustable cutting lengths (digital stops) | 1 or 2 | ||

| The length of the loading pipe [m] | 3.0~6.5/8.5/12.5 | ||

| Minimum distance between two bumpers [mm] | 30 | ||

| Cutting speed [m/min] (275 mm cutting blade) | 44~263 | ||

| Spindle speed with inverter [rpm] | 50~304 | ||

| Cutting disc diameter [mm] | 175~275 | ||

| Feeding speed [m/s] | 0.35~2.8 | ||

| Pump motor power [kW] | 3.75 | ||

| Type of cutting disc cooling | Sprayed with oil mist or closed circuit water | ||

| Cutting head motor power [kW] | 5.5 | ||

| Maximum weight [kg] for a length of 3000 mm | SA-76NC 2500 MB6 1200 |

SA-76NC 2500 MB6 1200 BDB-70 4000 |

|

| Specification | BDB-70 (model3) | |

|---|---|---|

| Detail dimensions mm | Tube | 12,5 – 76 |

| Square profile | 12,5x12,5 – 70x70 | |

| Rectangular profile | 15x10 – 80x70 | |

| Material length | 300 – 3000 | |

| Measurement tolerance | -------- | |

| Dimensions | 5900x2600x1500 | |

| Weight | 5300 | |

Standard equipment:

- Magazine with a pipe feeder 6 meters (MB) (option 12m)

- SOCO i2 control system integrated control system for controlling individual stages of the cutting process

- Inverter for speed control

- Bumpers with digital readout 1 piece (option 2 pcs)

- Toolbox

- DTR in English

- CE Declaration of Conformity

Optional equipment (payable additionally):

- Additional bumper with digital readout

- A set of nylon protections (to minimize scratches on the cut material)

- Feed rollers

- Feed rolls from stock

- Chains

- Jaws

- The machine can work together with the BDB - 70 - 3 deburring machine

Recommended

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.