Machine categories

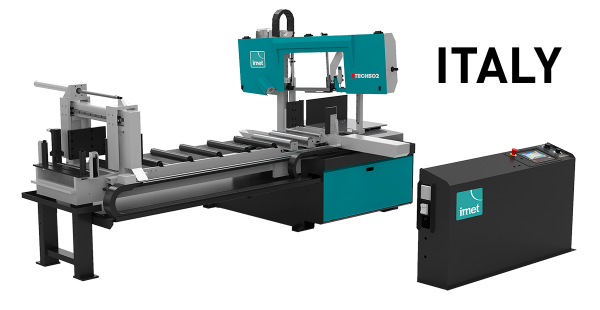

IMET KTECH 502 F2000 automatic column band saw

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

KTECH 502 is a two-column automatic band saw that includes the most advanced CNC technology available for cutting profiles at an angle of 60° to the right and left. KTECH has a 10-inch touchscreen interface for managing the cutting process and entering the project.

Quantity

Add to cart

Optional equipment (additionally paid):

Blade deviation control

It allows to always have cutting process with the right tollerance. It's possibile to set the preferred tollerance based on the needs for a specific material or cutting angle (maximum tollerance: 0.2mm).

Bundle cutting device

Hydraulic bundle cutting device which maximum cutting capacity is 500x250 while minimum capacity is 130x20mm. Minimum scrap-end with bundle cutting is 200mm. it's possibile to use the machine for mitre cutting just by disassembling the pressure device.

Bundle cutting device

Wraz z dociskiem umieszczonym obok imadła, rozcięcie wiązki odbywa się także za pomocą urządzenia uzupełniającego umieszczonego na zintegrowanym podajniku na zewnętrznej części szczęk podajnika. Tego urządzenia nie wolno zdejmować w celu cięcia ukośnego.

Promień lasera

To ease the working process, it's possibile to require di special laser ray that points the cutting line on the material before starting to operate.

Industry 4.0 Ready - SAWFACTORY

IMET automatic machines can be connected to the company network and be used remotely thanks SAWFACTORY and modem. SAWFACTORY is a dedicated software which allows to manage the cutting process from the office desk by setting cutting programs and monitoring the workflow thanks to the dedicated web app. The software also allows to also receive assistance by our technicians remotely.

Industry 4.0 Ready - OneLoad for MES

The kit allows to load from the company office/MES to the machine software a cutting list/program to optimize the internal workflow while avoiding possible mistakes made by the machine operator. It's necessary, for the customer, to have an FTP server on te same LAN where both SAWprogram software and cutting program are installed. A "shortcut" is enabled on the machine control to load the cutting lists and start the cycle (the kit is available only if the "Industry 4.0 Ready" package is already installed).

Industry 4.0 Ready - RealTime for MES

The kit allows to send directly from the machine to the MES information in real time about: machine status, cut pieces situation, automatic cycle progession. The connection is provided via a Web service made available by the user on his own LAN; the webservice will act as a filter between the bandsaw and the internal MES (the kit is available only if the "Industry 4.0 Ready" package is already installed)

Marking system

It's available for KTECH 502-652 models the automatic ink marking system that allows to impress a code on cut pieces to ease the material seleciton after the cut: the marking systems works before the cut and its programmaing is integrated with the machine CNC (allowing to create a unique program via KTECH touch screen) but it's equipped with its own independent touch screen display.

Sawframe downfeed with ballscrew

It's available upon request the sawframe downfeed descent by ballscrew and servomotor. Adding this features, the user can access to the automatic parmeters system and internal material library that he can also expand with its customized parameters. The option also include the controlled movement of the blade guide and the possibility to control the unloading device.

Metal protection barriers

According to CE law, it's also available the protection safety system made by metallic barriers that covers the machine on the 4 side with CNC managed access doors to regulate and control the operator access to the working area.

Safety photocells

It's possible, if the user doesn't want a full metallic barriers protection system, to install a pair ofl photocells instead of one of the metallic side.

| Technical data | Unit | Value |

|---|---|---|

| The width of the cutting band | [mm] | 34 |

| Vise opening width | [mm] | 500 |

| The dimensions of the cutting band | [mm] | 4250x34x1.1 |

| Cutting band speed | [m/min] | 0-100 |

| Cutting band motor power | [kW] | 2.2 |

| Working height | [mm] | 845 |

| Final waste | [mm] | 240 |

| Length of a single pass | [mm] | 2000 |

| Dimensions | [mm] | 3700x2300x2180 |

| Weight | [kg] | 2250 |

Recommended

Newsletter