Machine categories

Band saws

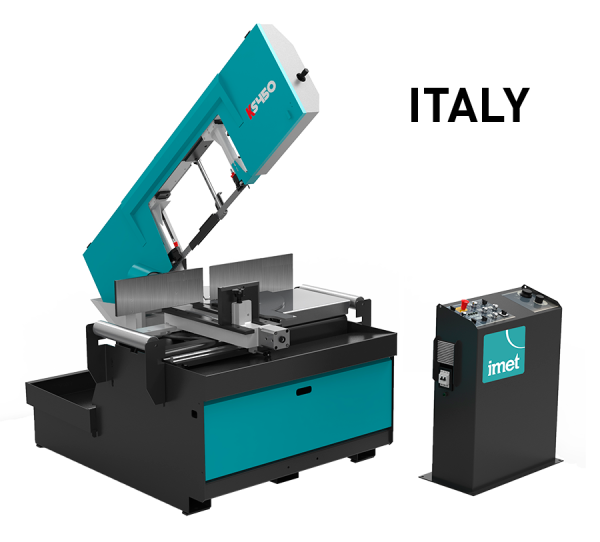

IMET KS 450 semi-automatic bandsaw

84 195,00 zł net

No rating

12 months of warranty

Contact with a trader:

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

IMET KS 450 is a semi-automatic saw designed, designed and developed for cutting metal structures, pipes, profiles and beams. The KS 450 is the only saw in its class that can cut up to 60° right and left after setting the locking vice once.

Quantity

Add to cart

Positioning the vice and material

The opening vice has 460 mm sliding transversely on the work surface, linear guides, locking and quick approach, complete with a standard pressure reducer. All KS series saws (450, 502, 620 and 652) allow you to attach a vice to press the material once and then rotate the arc to cut both right and left (up to 60°).

Worktable

The KS 450 worktable has a height of 845 mm and is integrated with the arc and blade passage, so it can hold material at any angle.

Graduated scale

To achieve better and higher cutting precision, a scale (away from the center of the machine for easier reading) is used as a visual reference with automatic stops at 0° and 45° (right and left).

Steel saw frame

The KS 450 is equipped with a rigid, welded steel tube arch and 360 mm diameter pulleys. The arc rotates using a pre-tensioned bearing.

Angled blade

The KS 450 and all KS series saws finish cutting with a blade inclined at an angle of 6°, which facilitates the penetration of the blade into the material and allows you to always cut a fragment of the material even in the presence of solid objects.

Bimetallic blade

The blade has dimensions of 4250x34x1.1mm. The height of 34mm allows the blade to better penetrate the material, allowing for maximum efficiency in the entire process. The blade tension is 2000kg/cm2 with a micro-switch control and immediate stop in case of breakage. KS 450 is standardly equipped with an inverter speed controller (18-100 m/min).

UMaterial detection device

To make it easier for the blade to approach the material, the KS450 has a device for automatically detecting the starting and ending point of cutting. The machine offers the option of removing the device if you want to increase cutting efficiency at 0° and 45° (right and left).

Cleaning the blades

Motorized nylon blade cleaning brush, driven by the motor pulley to always keep the cutting blade in perfect condition.

Control console

The KS 450 is equipped with a mobile control console with an LED that controls blade tension, blade guard opening, motor thermal lock and electrical voltage. Using the controller, the operator can choose between 3 different ways to complete the cut: raising the arc with the blade stopped, raising the arc with the blade moving, and ending the cycle without lifting the arc.

Device features:

Device features:

- Maximum cutting diameter: ø 350 mm (with arm height sensor turned off)

- Working feed: gravity arm drop; smooth regulation

- Arm lifting: hydraulic

- Angle cutting: right 0° - 45° - 60°; left 0° - 45° - 60°

- Cutting band dimensions: 4250 x 34 x 1.1mm

- Belt speed: 15 - 100 m/min (stepless adjustment)

- Hydraulic vice

Standard equipment:

- Cooling system

- Bimetallic tape – 1 piece in the machine

- User manual in English

- CE certificate

Optional equipment (additionally paid):

- Roller feeders

- Measure with bumper

- Connector

- Oil mist lubrication system (micronizer)

- Strain gauge for precise setting of belt tension

| Technical data | Unit | Value |

|---|---|---|

| The width of the cutting band | [mm] | 34 |

| Vise opening width | [mm] | 450 |

| The dimensions of the cutting band | [mm] | 4250x34x1,1 |

| Cutting band speed | [m/min] | 15-100 |

| Cutting band motor power | [kW] | 2.2 |

| Working height | [mm] | 845 |

| Dimensions | [mm] | 1400x2250x2180 |

| Weight | [kg] | 980 |

Recommended

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.