CNC machining center

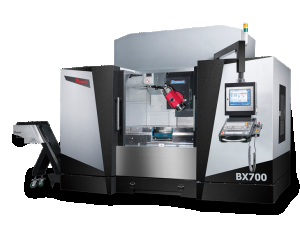

EUROMET SKOLAR iX5 5-axis CNC machining center

138 200,00 zł net

No rating

12 months of warranty

Contact with a trader:

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

SKOLAR iX5 is a small, 5-axis CNC machining center designed for teaching institutions. It provides high educational values with low financial outlays. A unique feature of this machine is the ability to work with the USW workstation, which allows you to simulate work on over 20 CNC systems. Skolar iX5 can connect to multiple USW stations at the same time, which allows more people to learn at the same time with just one machine tool.

SKOLAR iX5 is a small, 5-axis CNC machining center designed for teaching institutions. It provides high educational values with low financial outlays.

A unique feature of this machine is the ability to work with the USW workstation, which allows you to simulate work on over 20 CNC systems. Skolar iX5 can connect to multiple USW stations at the same time, which allows more people to learn at the same time with just one machine tool.

The Skolar iX5 machining center is an excellent tool for learning the profession of a CNC operator, but thanks to its high precision and efficiency, it will also work well in industrial plants.

The SKOLAR iX5 machining center can be connected to many USW workstations, allowing the entire group of students to work in parallel!

The SKOLAR iX5 machining center can be connected to many USW workstations, allowing the entire group of students to work in parallel!

Standard equipment and main features of the device:

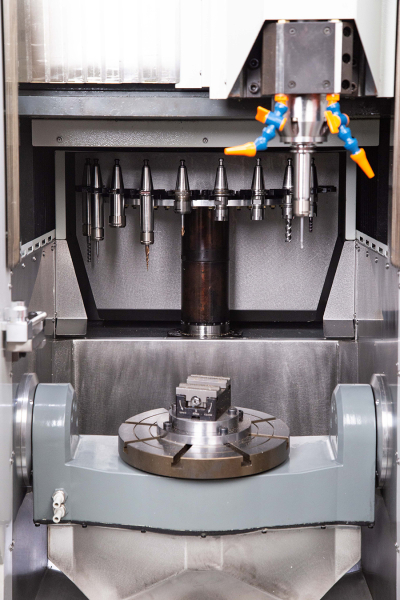

- Spindle 40,000 rpm

- 12T tool magazine

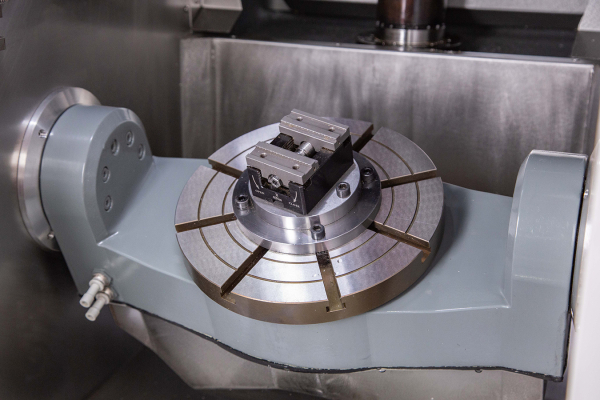

- Simultaneous 5-axis machining

- Completely enclosed workspace

- SIEG controller

- Cooling system

- Air gun

- Warning lights

- Workspace lighting

Optional equipment (for an additional fee):

USW – a workstation simulating work on controllers from various manufacturers (including Siemens, Fanuc, Heidenhein, Mitsubishi). Thanks to this device, students can practice programming in the simulator, and after finishing work on the virtual machine, upload the program to a real machine tool and physically perform the detail.

This is a great solution for teaching institutions because of the ability to learn many different CNC systems without having to purchase several machines. In addition, one machine tool can cooperate with many simulators, which makes our solution very economically profitable - a teaching laboratory can be equipped with only one machine tool and many USW stations.

The most important advantages of the USW workstation:

- over 20 CNC systems in one place

- possibility of cooperation of many USW workstations with one Skolar iX5 machine tool

- In addition to the virtual interface, USW workstations are equipped with a physical control panel that can reproduce the selected controller model (including Siemens, Fanuc, NHC)

- the teacher has the ability to monitor students' work in real time, as well as communicate with them and share the screen

| Technical data | Unit | Value |

|---|---|---|

| Table surface (length) | [mm] | 180 |

| Table surface (width) | [mm] | 180 |

| X axis travel | [mm] | 200 |

| Y axis travel | [mm] | 150 |

| Z axis travel | [mm] | 200 |

| Table load | [kg] | 20 |

| A axis rotation | [°] | +110/ -30 |

| C axis rotation | [°] | 360 |

| Spindle taper | [-] | ISO20 |

| Spindle speed | [rpm/min] | 0 - 40000 |

| Spindle motor power | [kW] | 2,2 |

| Spindle drive | [-] | bezpośredni |

| Rapid feed (X / Y / Z) | [m/min] | 9 |

| Working feed (X / Y / Z) | [m/min] | 6000 |

| Working feed (A / C) | [rpm/min] | 16,6 |

| Tool magazine capacity | [pcs] | 12 |

| Tool diameter | [mm] | 12 |

| Tool length | [mm] | 20 |

| X / Y / Z axis positioning accuracy | [mm] | ≤ 0,01 |

| Dokładność pozycjonowania osi A/C | [art-sec] | ≤ 40 |

| A / C axis positioning accuracy | [mm] | ≤ 0,005 |

| Accuracy of A / C axis re-positioning | [art-sec] | ≤ 20 |

| Tool change time | [s] | 5 |

| Dimensions (LxWxH) | [mm] | 1100 x 1200 x 1900 |

| Weight | [kg] | 800 |

Recommended

CNC machining center

470 787,42 zł

No rating

CNC machining center

Priced individually

No rating

CNC machining center

Priced individually

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.