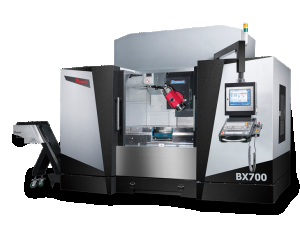

DMTG VDLS1000 cnc machining center

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

The DMTG VDLS1000 vertical CNC machining center is characterized by reliability, high parameters and processing efficiency. Built on a foundation characterized by high stiffness and stability, the full support load sliding table provides the ability to cope with heavy machining loads. The long-span inverted T-shaped column effectively reduces vibration and distortion during high-speed machining, while the high-speed direct drive spindle ensures high-quality machining.

Quantity

Add to cart

The VDLS series vertical machining center is a completely new CNC machine developed and manufactured by General Technology Group Dalian Machine Tool Co., Ltd. It is characterized by reliability, high parameters and machining efficiency. Built on a foundation characterized by high stiffness and stability, the full support load sliding table provides the ability to cope with heavy machining loads. The long-span inverted T-shaped column effectively reduces vibration and distortion during high-speed machining, while the high-speed direct drive spindle ensures high-quality machining. High chip removal efficiency enables users to work efficiently. It is an ideal choice for the production of single pieces, as well as for manufacturers in the automotive, energy and mechanical engineering industries.

* the photo shows additional equipment

- FANUC 0i MF(5) Plus controller

- 12,000 rpm spindle with direct drive

- 24-position tool magazine

- Oil-cooled spindle

- Accelerated travel in the X/Y/Z axes – 36/36/30 m/min

- Screw chip conveyor

- Spindle blow-by

- Rigid tapping function

- Compressed air gun

- Cooled electrical cabinet

- MPG knob

- USB port with DNC function (the machine can run a program on a pendrive)

- Coolant and oil distributor

- CE standard

- Alarm light

- Maintenance tools

- User manual in English

| Technical data | Unit | Value |

|---|---|---|

| Table surface (length) | [mm] | 1120 |

| Table surface (width) | [mm] | 560 |

| X axis travel | [mm] | 1040 |

| Y axis travel | [mm] | 580 |

| Z axis travel | [mm] | 620 |

| Table load | [kg] | 750 |

| T-slots (W x Pitch mm x °) | [-] | 18x100x5 |

| Distance between the spindle and the table | [mm] | 125-745 |

| Spindle taper | [-] | ISO40 |

| Spindle speed | [rpm/min] | 0 - 12000 |

| Distance from the spindle axis to the column surface | [mm] | 666 |

| Spindle motor power | [kW] | 7,5/11 |

| Rapid feed (X / Y / Z) | [m/min] | 36/36/30 |

| Working feed (X / Y / Z) | [m/min] | 1-10 |

| The power of FANUC feed servo motors | [kW] | 3 |

| Tool magazine type | [-] | Bębnowy |

| Tool magazine capacity | [pcs] | 24 |

| Tool diameter | [mm] | Ø78 / Ø155 |

| Tool weight | [kg] | 8 |

| X / Y / Z axis positioning accuracy | [mm] | 0,016 / 0,008 / 0,008 |

| A / C axis positioning accuracy | [mm] | 0,006 / 0,005 / 0,005 |

| Tool change time | [s] | 2,7 |

| Dimensions (LxWxH) | [mm] | 2800 x 2671 x 2820 |

| Weight | [kg] | 7000 |

Recommended

Newsletter