Didactic lathes

TR Educational Stand

199 300,00 zł net

No rating

12 months of warranty

Contact with a trader:

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

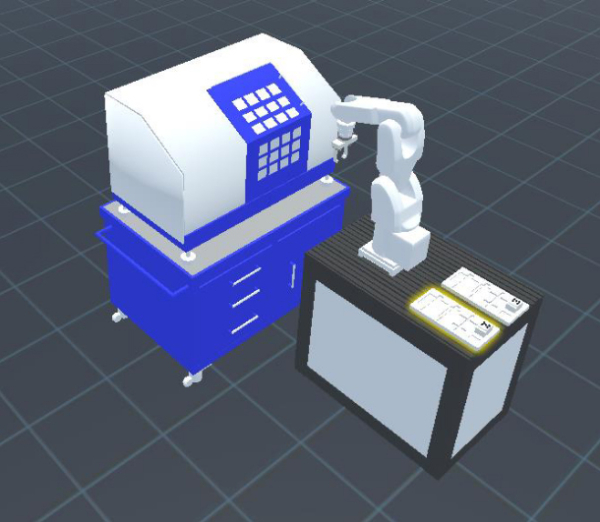

CNC lathe with 6-axis robot with pneumatic chuck.

Quantity

Add to cart

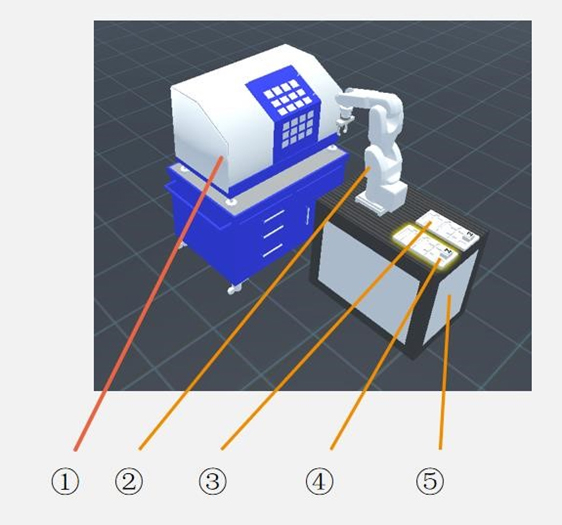

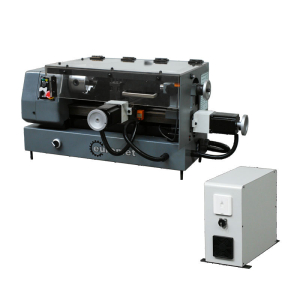

① Skolar i4S CNC Lathe with Pneumatic Door, Pneumatic Chuck and I/O Communication Port.

② 6-axis Robot with Pneumatic Chuck (Recommended Effort Brand).

③ Raw Parts Library, 6 Stations, Made of Aluminum, Adapted to Part Shape

④ Finished Parts Library, 6 Stations, Made of Aluminum, Adapted to Part Shape.

⑤ Robot Base is made of Aluminum Alloy and Sheet Metal, with 4 Wheels at the Bottom. On the Top of the Base is Robot, Raw Parts Library, Finished Parts Library. And the Control Component is Installed Inside the Base.

Knowledge and Skills That Can Be Achieved:

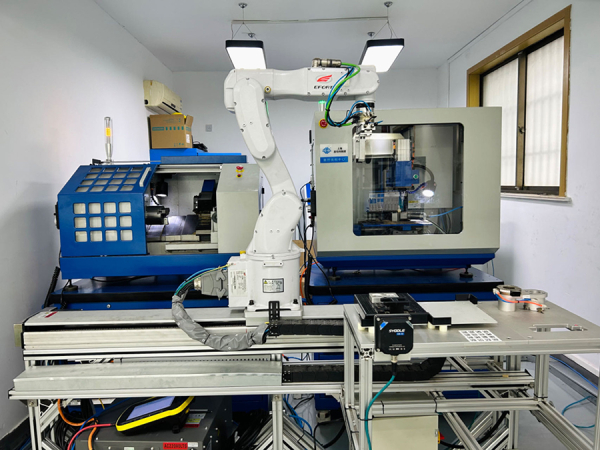

TR Lathe Loading and Unloading Workstation, Machine Tool Module and Robot Module have Movable Wheels at the Bottom. The I/O communication port between the machine tool and the robot is installed outside the machine housing. The separation and connection of the workstation is quick and convenient.

- The TR workstation allows for independent training and operation of the CNC machine tool and robot, as well as CNC machining programming and robot control.

- It can perform automatic loading and unloading functions and programming of on-the-job training.

- It allows for training of the robot in the field of parts handling between two part libraries.

- It allows for learning about communication and information exchange between the CNC machine tool and the robot.

* Illustrative photo of the machine, in reality it may differ in details or parameters.

Recommended

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.