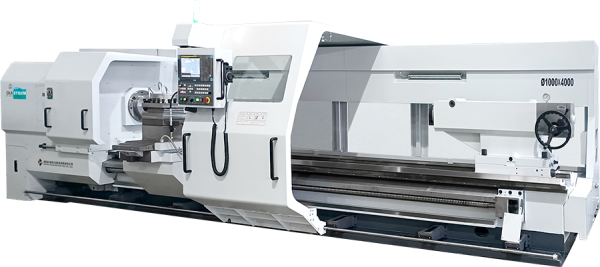

CNC LATHE DMTG CKE61100M x 5000

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

CKE-M series machines are horizontal CNC lathes with a flat bed with control in two axes: vertical (Z) and horizontal (X). They are capable of automatically performing machining processes such as internal and external cylindrical surfaces, conical surfaces, circular arc surfaces, end faces, grooving and chamfering for large shaft and disk-like parts. They can also perform a variety of turning processes, including metric straight threads, face threads, straight inch threads, and tapered threads.

CKE-M series machines are horizontal CNC lathes with a flat bed with control in two axes: vertical (Z) and horizontal (X). They are capable of automatically performing machining processes such as internal and external cylindrical surfaces, conical surfaces, circular arc surfaces, end faces, grooving and chamfering for large shaft and disk-like parts. They can also perform a variety of turning processes, including metric straight threads, face threads, straight inch threads, and tapered threads. The CKA61100M and CKA61125M models use CNC systems from international companies such as FANUC or Siemens, enabling multiple, repeatable detail machining cycles. It is suitable for the production of a variety of products in large quantities and particularly excels in the machining of complex and precise parts.

- The machine tool has a traditional horizontal lathe layout. The overall structure is characterized by good rigidity and complies with safety standards. The main foundation elements, such as the bed, headstock, saddle and tailstock, are manufactured using modern resin sand casting, which contributes to the excellent stability of the machine.

- For precision-related parts such as the bed, tailstock, lead screws and supports, the design and machining accuracy have been carefully optimized. Additional assembly control measures have been introduced to increase the machining precision of the machine tool, ensuring a consistent, stable and machine tool design integrates mechanical and electrical components, resulting in a compact and rational overall layout. It offers user-friendly operation and ease of maintenance.

- The machine tool has a modular structure, which allows for various configurations depending on the user's requirements (e.g. system configuration). This design flexibility meets the different needs for machining different types of workpieces.

- Servo spindle motor

- Fanuc 0i-TF (1) Plus system

- 4-jaw manual chuck

- Vertical 4-position knife holder

- Manual tailstock (<4000mm), electric tailstock (>4000)

- Chip conveyor

- Heat exchanger

- CE certificate

- User manual in English

- Siemens system

- Fixed support

- Movable rest

- Air conditioner

| Technical data | Unit | Value |

|---|---|---|

| Turning diameter over bed | [mm] | 1000 |

| Turning diameter over slide | [mm] | 630 |

| Workpiece length | [mm] | 5000 |

| X-axis travel range | [mm] | 520 |

| Z axis travel range | [mm] | 5000 |

| Rotation speed | [rpm/min] | 500 |

| Spindle tip | [-] | A2-15 |

| Spindle flight | [mm] | 130 |

| X / Z accelerated feed | [m/min] | 6/8 |

| Tailstock sleeve diameter | [mm] | 200 |

| Tailstock taper | [-] | MT 6 |

| Main spindle motor | [kW] | 22/26 (FANUC) |

| Longitudinal feed | [mm/rpm] | 2 - 315 |

| Max. rotation diameter over bed | [mm] | 1000 |

| Tool shank size | [mm] | 40X40 |

| Tailstock step | [mm] | 300 |

| Positioning accuracy of the X/Z axis (C, Y) | [mm] | 0,03 |

| Repeatability accuracy of the X/Z axis (C, Y) | [mm] | 0,008 / 0,014 |

| External dimensions L x W x H | [mm] | 9820 x 2300 x 2000 |

| Net weight | [kg] | 17000 |

Recommended

Newsletter