Surface grinding machines

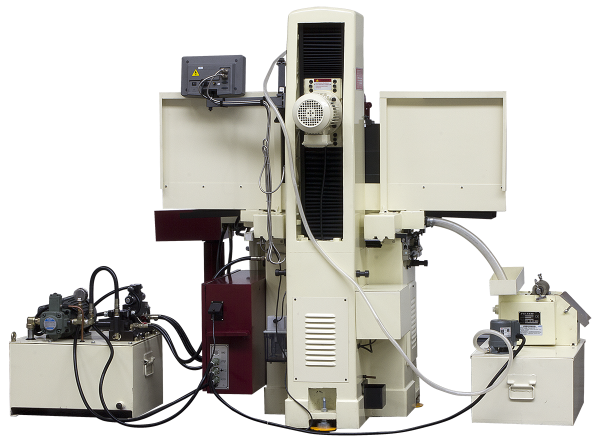

Automatic surface grinding machine KENT KGS 818 SD1 / SD2

Priced individually

No rating

12 months of warranty

Contact with a trader:

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

KENT USA KGS 818 SD1/SD2 automatic surface grinding machine equipped with a Siemens PLC controller and a Siemens servo motor responsible for controlling the vertical travel of the headstock (Z axis). Automatic vertical feed of 0.001-0.1mm/pass and 0.01 pitch for transverse feed (Y-axis) provide the ability to perform rough grinding, finishing and sparking in one work cycle. Z axis ball screw - Taiwanese production, Y axis ball screw - Chinese production.

The KENT USA KGS 818 SD1/SD2 automatic surface grinder uses the Siemens + MPG PLC controller and is a machine with the ability to program a full cycle of detail grinding. Extended versions of KGS AHS grinders, equipped with a touch control panel, are available in two basic versions:

KGS SD1 - Grinding machine equipped with a PLC controller and a servomotor responsible for controlling the vertical travel of the headstock. Automatic vertical feed of 0.001-0.1mm/pass provides the ability to perform rough grinding, finishing and sparking out in one work cycle.

KGS SD2 - Grinding machine equipped with two servo motors that operate the vertical feed of the headstock and the transverse feed of the working table. Thanks to the automatic transverse feed with the possibility of a precise feed of 0.001mm/pass, it is possible to precisely grind the vertical edges of the detail, grooves or grooves.

Each KGS grinder, equipped with a hydraulic drive for longitudinal travel of the working table, can be available in the SD1 or SD2 version.

Small workpieces may be less well held by an electromagnetic table with a standard pitch. In order to ensure proper holding of small workpieces, an electromagnetic table with a smaller pitch (option) should be used.

The clamping force of the electromagnetic table is min. 100N / cm2. Alloy and high-alloy steels, due to the lower iron content, can be less well kept on the electromagnetic table. It should be remembered that materials such as copper, nickel, bronze and their alloys are diamagnets.

Standard equipment:

- Grinding wheel

- Rear guard

- Magnetic table

- PLC controller with Siemens touch panel

- MPG knob

- Vertical and transverse feed ball screw

- Vertical feed servo in SD1 machines

- Servo motor for vertical and lateral feed in SD2 machines

- Static wheel balancer

- CE declaration of conformity

- User manual in English

Optional equipment (additionally payable):

- Sustaining the table's operation in the event of a power failure - UPS

- Device for parallel dressing of the grinding wheel

- Device for dressing the grinding wheel at an angle

- Basic magnetic separator

- Magnetic separator with coolant pump and paper filter

| Technical data | Unit | Value |

|---|---|---|

| The width of the table | [mm] | 200 |

| Table length | [mm] | 460 |

| Longitudinal feed | [mm] | 510 |

| Cross feed | [mm] | 250 |

| Distance from the table surface to the spindle axis | [mm] | 530 |

| Maximum table load | [kg] | 150 |

| T-slot for table clamping | [mm] | 1 x 14 |

| Table speed | [m/min] | 0 - 25 |

| Transverse travel per 1 division of the vernier scale | [mm] | 0,02 |

| Transverse travel per revolution of the wheel | [mm] | 5 |

| Transverse automatic feed per cut (SD1) | [mm] | 0,5 – 12 |

| Transverse automatic feed per cut (SD2) | [mm] | 0,001/0,01/0,1 |

| Accelerated cross feed | [mm/min] | 780 |

| Grinding wheel size | [mm] | 200 x 25 x 32 |

| Spindle rotation | [rpm/min] | 0 - 2850 |

| Feed per revolution of the MGP wheel | [-] | x1, x10, x100 |

| Minimal automatic vertical feed | [mm] | 0,001 |

| Main engine power | [kW] | 1,5 |

| Hydraulic pump motor power | [kW] | 1,5 |

| Coolant pump motor power | [W] | 90 |

| Cross feed motor power | [W] | 60 |

| Floor area occupied | [mm] | 2500 x 1900 |

| Weight | [kg] | 1320 |

Recommended

Surface grinding machines

No rating

Surface grinding machines

49 375,89 zł

No rating

Surface grinding machines

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.