Surface grinding machines

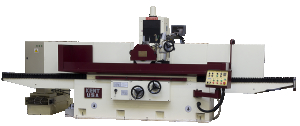

Automatic surface grinder KGS 1020 AHS

No rating

12 months of warranty

Contact with a trader:

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

The automatic surface grinder KGS 1020 AHS is produced by the well-known company KAITE. Grinders are used in all industrial plants, they are designed for continuous operation. Drive for the Y / Z axis Siemens servo motor controlled by Siemens PLC, cross feed pitch 0.01mm, auto feed pitch (Z - down) 0.002, for the Y axis a Chinese ball screw, and for the Z axis - a trapezoidal screw.

Quantity

Add to cart

The KGS 1020 AHS automatic surface grinder is manufactured by the KAITE company, known for years on the market. Drive for the Y / Z axis Siemens servo motor controlled by Siemens PLC, cross feed pitch 0.01mm, auto feed pitch (Z - down) 0.002, for the Y axis a Chinese ball screw, and for the Z axis - a trapezoidal screw. It is characterized by a modern and stable construction. The main bodies are made as precise iron castings. Thanks to this, the structure is sufficiently heavy and stiff, and dampens vibrations. The grinder has a very rich standard equipment. The longitudinal movement of the table is carried out hydraulically, with smooth speed regulation.

The spindle is based on angular contact bearings. The tension of the bearings ensures backlash-free operation of the spindle, thanks to which grinding accuracy of up to 2 microns can be obtained.

The hydraulic system based on specially designed valves ensures a gentle change of the direction of the table movement, without significant overloads and jerks.

Small workpieces may be less well held by an electromagnetic table with a standard pitch. In order to ensure proper holding of small workpieces, an electromagnetic table with a smaller pitch (option) should be used.

Standard equipment:

- Grinding wheel

- Rear guard

- Magnetic table

- Automatic feed for 2 axes

- Ball screw for Y-axis, trapezoidal for Z

- Microfeed

- Static wheel balancer

- CE declaration of conformity

- User manual in English

Optional equipment (additionally payable):

- Sustaining the table's operation in the event of a power failure - UPS

- Device for parallel dressing of the grinding wheel

- Device for dressing the grinding wheel at an angle

- Basic magnetic separator

- Magnetic separator with coolant pump and paper filter

- Digital readout for 2 axes

| Technical data | Unit | Value |

|---|---|---|

| The width of the table | [mm] | 255 |

| Table length | [mm] | 510 |

| Longitudinal feed | [mm] | 575 |

| Cross feed | [mm] | 280 |

| Distance from the table surface to the spindle axis | [mm] | 535 |

| Maximum table load | [kg] | 300 |

| T-slot for table clamping | [mm] | 1 x 14 |

| Table speed | [m/min] | 5 - 25 |

| Transverse travel per 1 division of the vernier scale | [mm] | 0,02 |

| Transverse travel per revolution of the wheel | [mm] | 5 |

| Transverse automatic feed per cut (SD1) | [mm] | 2 |

| Transverse automatic feed per cut (SD2) | [mm] | 0,01 |

| Accelerated cross feed | [mm/min] | 790 |

| Grinding wheel size | [mm] | 200 x 25 x 32 |

| Spindle rotation | [rpm/min] | 0 - 2850 |

| Feed per revolution of the MGP wheel | [-] | x1, x10, x100 |

| Minimal automatic vertical feed | [mm] | 0,005/0,1/0,015/0,02/0,025/ 0,03/0,04/0,05 |

| Main engine power | [kW] | 2,2 |

| Hydraulic pump motor power | [kW] | 1,5 |

| Coolant pump motor power | [W] | 90 |

| Cross feed motor power | [W] | 60 |

| Floor area occupied | [mm] | 1900 x 2300 |

| Weight | [kg] | 1680 |

Recommended

Surface grinding machines

No rating

Surface grinding machines

62 110,08 zł

No rating

Surface grinding machines

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.