Mechanical presses

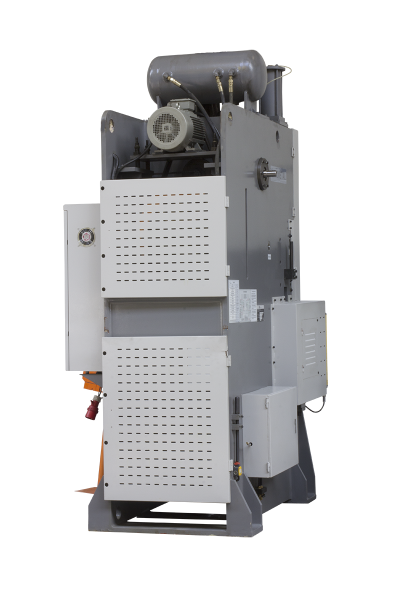

EUROMET JL21-200T MECHANICAL PRESS

Priced individually

No rating

12 months of warranty

Contact with a trader:

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

EUROMET JL21 series eccentric presses have a PLC controller as standard. The crankshaft is positioned in the longitudinal direction. The presses use a combination of a pneumatic, dry friction clutch and a brake, which makes the stroke engagement smooth.

EUROMET JL21 series eccentric presses have a PLC controller as standard. The crankshaft is positioned in the longitudinal direction. The presses use a combination of a pneumatic, dry friction clutch and a brake, which makes the stroke engagement smooth.

The gear train operates in an oil bath and is splash lubricated. The slider has the shape of a cuboid and moves along guides. A hydraulic overload safety device is mounted on the slider. The tool setting is regulated by an electric motor. The press is equipped with a pressure accumulator, automatic feed shaft and light curtain.

The pressure of the presses ranges from 25 tons to 250 tons. The maximum height of a set of dies is from 250 to 500 mm. Other functional parameters on request.

The press has an EC type examination issued by a notified body.

Standard equipment:

- Anti-crash light curtain

- Slider stroke adjustment

- Large table with T-slots

- Overload fuse

- Air operated clutch

- PLC driver

- Regulation of the number of jumps

- User manual in English

- CE declaration of conformity, type examination

Optional equipment (for an additional fee):

- Feeder

- Uncoiler

- Straightener

- Detail ejector

- Rewinder

| Technical data | Unit | Value |

|---|---|---|

| Pressure | [KN] | 2000 |

| Stroke under nominal load | [mm] | 6 |

| Ram stroke | [mm] | 19 - 180 |

| The number of strokes | [1/min] | 30 - 50 |

| Die set height max | [mm] | 450 |

| Die height adjustment | [mm] | 110 |

| Recess | [mm] | 390 |

| Wall spacing | [mm] | 870 |

| Working table width | [mm] | 1400 |

| The length of the working table | [mm] | 760 |

| Thickness of the working table | [mm] | 160 |

| Worktable hole diameter (outer) | [mm] | Ф300 |

| Worktable hole diameter (depth) | [mm] | 50 |

| Worktable hole diameter (internal) | [mm] | Ф260 |

| The width of the bottom of the slider | [mm] | 920 |

| Length of the bottom of the zipper | [mm] | 600 |

| The diameter of the hole for the stamp | [mm] | Ф65 |

| The depth of the hole for the stamp | [mm] | 90 |

| Engine power | [kW] | 18,5 |

| Overall dimensions (WxLxH) | [mm] | 2500x1580x3420 |

| Weight | [kg] | 16500 |

Recommended

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.