Pipe and section bending machines - with mandrel

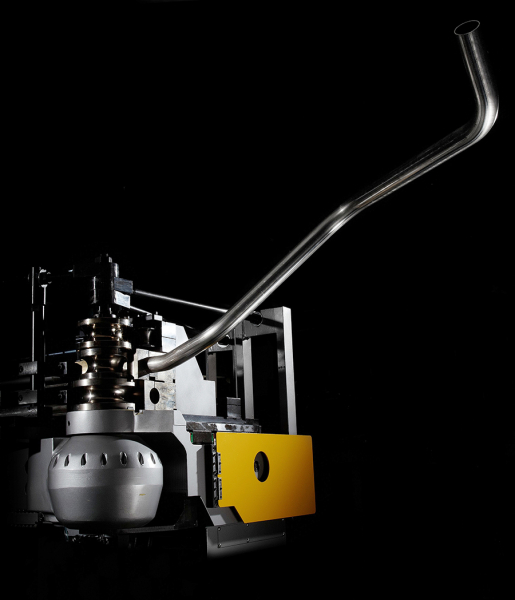

SOCO SB-90x7A-MR CNC pipe bender (MRV)

Priced individually

No rating

12 months of warranty

Contact with a trader:

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

SOCO MRV, MRV series hydraulic bending machines equipped with CNC control and servo motor drives for 6 axes, with the possibility of mounting up to 6 stacks of dies. They are intended for complex bending with both small and large bending radii. They also enable 1D bending and bending with zero clamp length. The unique DGT bending head drive system, using a gear transmission and a servo motor drive, ensures even greater bending efficiency and stability.

SOCO MRV, MRV series hydraulic bending machines equipped with CNC control and servo motor drives for 6 axes, with the possibility of mounting up to 6 stacks of dies. They are intended for complex bending with both small and large bending radii. They also enable 1D bending and bending with zero clamp length. The unique DGT bending head drive system, using a gear transmission and a servo motor drive, ensures even greater bending efficiency and stability.

Main features of the device:

- Unique head design – DGT system

- 6 controlled axes (Feed – Y, rotation – B, horizontal head movement – X, bending – C, supporting the pressure matrix – V1, vertical head movement – V2)

- All 6 axes can be controlled simultaneously

- The possibility of mounting up to 6 stacks of dies allows bending even very complex details in one mounting

- CNC controller with touch screen

- The tube carriage is fed using a toothed rack and a servomotor

- Possibility to mount multiple stacks of dies and rolls – for large radii

- Programmable force of the supporting device for 1D bending

- Programmable arc length for large radii

- Material elasticity compensation for roll bending

- Compensation for die bending

- Entering data in the YBC and XYZ system

- Possibility to convert data from XYZ to YBC

- The bending arm is equipped with an additional actuator supporting the bending process - booster

- Electrical system equipped with a cooling system

- Automatic lubrication system for the mandrel increases its life as well as the quality and accuracy of bending

- Smoothing die support with lubrication

- The control panel is placed on a movable base, enabling the most favorable positioning for the operator

Standard equipment:

- Early pin retraction system

- Automatic pin lubrication system

- Central lubrication system

- Bending die support system

- Portable control panel

- User manual in English

- CE Declaration of Conformity

| Technical data | Unit | Value |

|---|---|---|

| Diameter of the bent pipe (steel) | [mm] | 2.2 - 88.9 |

| Diameter of the bent pipe (stainless steel) | [mm] | 1.5 - 88.9 |

| Tube length with mandrel | [mm] | 4600 |

| Bending radius | [mm] | 250 |

| Bending angle | [°] | 190 |

| Bending accuracy | [°] | +/- 0,1 |

| The accuracy of the positioning movements | [°] | +/- 0,1 |

| Accuracy of the feed | [°] | +/- 0,1 |

| The difference between the radiuses | [mm] | 80 |

| Die bending radius - profile | [mm] | 1,5D – 5D |

| Die bending radius - pipe | [mm] | 2D – 5D |

| Bending radius on rollers - pipe | [mm] | 8D - ∞ (MRV) |

| Roller bending radius - profile | [mm] | 12D - ∞ |

| 1D bending | [-] | Nie (MR) / Tak (MRV) |

| Die radius difference | [mm] | 30 |

| Dimensions | [mm] | 7000x 2100x 1700 |

| Weight | [kg] | 10100 |

Recommended

Pipe and section bending machines - with mandrel

527 991,03 zł

No rating

Pipe and section bending machines - with mandrel

579 883,50 zł

No rating

Pipe and section bending machines - with mandrel

1 094 055,48 zł

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.