Dynamitech DynaTurn 102 CNC lathe

The Czech-made DynaTurn 102 CNC lathe is suitable for turning both simple and very complex details, both in piece and series production.

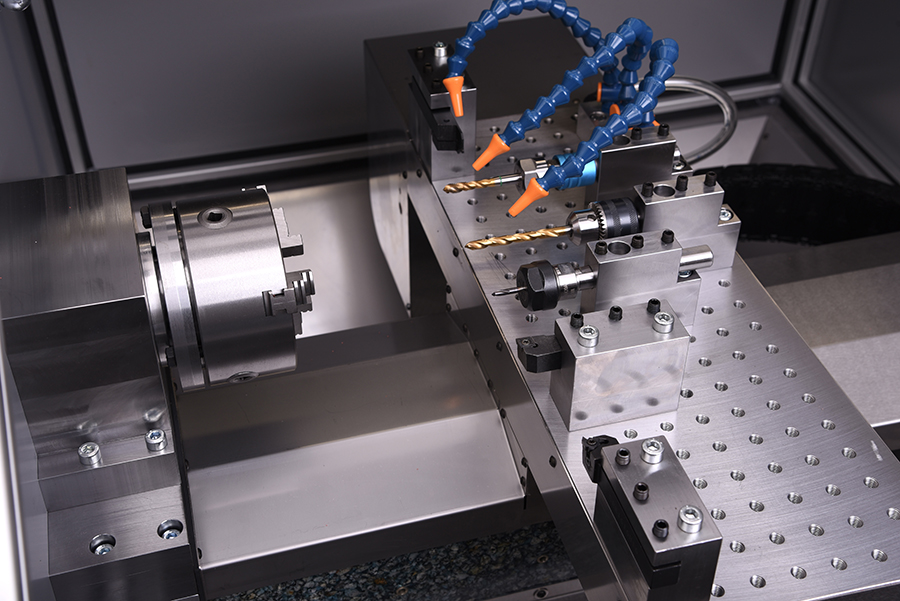

The machine spindle is hardened, made of high-quality steel and placed in tapered roller bearings. This is the basic condition for smooth operation without unwanted vibrations. The spindle drive is provided by a SIMOTICS asynchronous motor with precise positioning. Thanks to appropriate accessories, it is possible to install driven tools on the machine, e.g. for boring holes in the face, milling slots, etc.

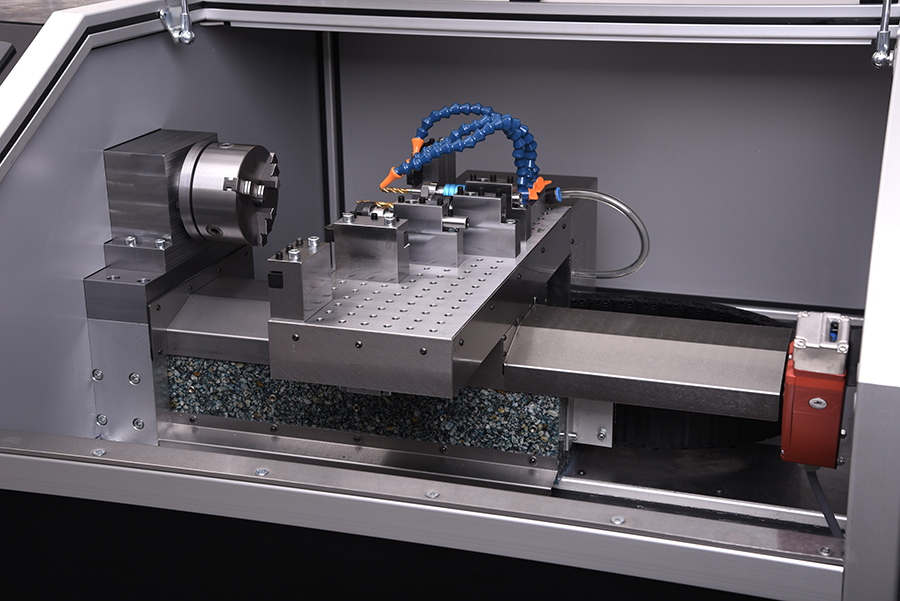

Due to the size of the machine, high stiffness was achieved. This is mainly due to the kinematic system and a very massive deposit of cast "mineral cast" granite. The longitudinal and transverse supports together form a solid cross table placed in a tensioned BoschRexroth roller guide. The machine can easily process difficult-to-process materials such as stainless steel, titanium, etc.

The pressure plate of the cross slide is equipped with a thread grid enabling variable arrangement of front and radial tool holders. This solution is a natural guarantee of high stiffness, speed and accuracy of the approach.

All moving parts are covered with a stainless steel plate and arranged in such a way that the chips fall without stopping in the collection tank. This solution not only greatly facilitates operation, maintenance and adjustment, but also significantly reduces the rate of wear. There is a coolant tank with a pump under the oil pan.

Main features of the machine:

- Bed structure - granite composite "mineral cast".

- Spindle - hardened quality steel, placed in tapered roller bearings, driven by a SIMOTICS asynchronous motor with precise positioning - can be used in driven tools.

- Linear guide - BoschRexroth size 25, tensioned.

- Ball screws – BoschRexroth size 20, pre-tensioned.

- Axis drive – SIMOTICS digital servo motors with absolute measurement and direct connection to the ball screw.

- CNC system - SIEMENS SINUMERIK 808 D ADVANCED, workshop programming including standard turning cycles, hand wheel.

- Warranty - workshop service, used branded components, SINUMERIK control system - all this allows us to provide the user with a standard warranty of 36 months for single-shift operation.

- jednozmianową.

Control system

The machine is equipped with the world-famous SIEMENS SINUMERIK 808 D ADVANCED control system, digital SIMOTICS motors with an absolute sensor and SINAMICS V70 servo drives. A friendly user interface with a workshop cycle programming module allows you to quickly create simple and more complex programs for both single-piece and large-scale production.

More information and technical parameters can be found at this link or by clicking on the photos below.

More information and technical parameters can be found at this link or by clicking on the photos below.

Date of publication: 27.03.2024