CNC Lathes

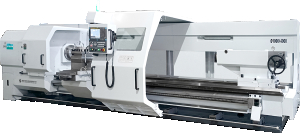

DMTG DT-30H CNC LATHE

Priced individually

No rating

12 months of warranty

Contact with a trader:

Krzysztof Penkowski

E-mail: krzysztof.penkowski@eurometal.com.pl

Telefon: 603 400 333

Krzysztof Penkowski

E-mail: krzysztof.penkowski@eurometal.com.pl

Telefon: 603 400 333

The DMTG DT-30H CNC lathe with an inclined bed is widely used for machining elements such as shafts and disc parts that are used in the petrochemical and mining industries in industries such as: automotive, production of molds, bearings, production of petroleum machinery. Automation of many operations, such as turning and boring, with one workpiece clamping.

The DMTG DT-30H CNC lathe with an inclined bed is widely used for machining elements such as shafts and disc parts that are used in the petrochemical and mining industries in industries such as: automotive, production of molds, bearings, production of petroleum machinery. Automation of many operations, such as turning and boring, with one workpiece clamping.

Machine Features:

- Configurable chip transport, ready for integration into production lines.

- A spacious work area that can accommodate special tooling, automatic loading and unloading and other specialized equipment, making it particularly suitable for integration into production lines.

- Equipped with the Fanuc 0i-TF(5) system with USB ports and a 10.4" color LCD display.

- High Rigidity Construction: The bed is cast as a whole, with the bed guide rail inclined at 40°, providing a large cross-section, excellent stiffness and vibration absorption. This also ensures high cutting precision.

- High efficiency and low noise design: The main drive system of the machine uses AC servo motor drive combined with high efficiency parallel V-belt transmission to directly drive the spindle. This design avoids noise problems caused by the gear chains of the gearbox.

- High-speed, high-rigidity spindle: The front and rear ends of the spindle are equipped with precision, high-speed NSK spindle bearings with appropriate preload force. Combined with ideal span support and a box-type spindle housing, the spindle is characterized by high stiffness andpossibility of working at high speeds.

- Highly reliable hydraulic turret with high stiffness, ensuring high reliability and repeatable positioning accuracy.

- Precise and fast longitudinal and transverse drives. The machine uses ball screws and linear roller guides, ensuring high gear efficiency and good accuracy retention. This ensures fast and stable head movement tool, with high positioning accuracy.

- High precision hydraulic tailstock ensures accurate centering during turning operations.

- The automatic central lubrication system ensures continuous and effective lubrication of guides and ball screws.

- Complete housing for protection. The machine is completely enclosed to prevent coolant leaks. The industrial style design, left sliding door and right control panel layout, provides an aesthetic appearance that emphasizes functionality, ensuring operators are safe and comfortable working environment.

- The independent chip and cooling system is equipped with a high-flow cooling pump and chain chip conveyor, ensuring forced cooling and automatic chip removal during turning operations.

Standard equipment:

- 12-position hydraulic tool tower

- nsk spindle bearings and x/z axis bearings

- x/z ball screws and x/z linear guides

- Hydraulic chuck without through hole

- Hydraulic tailstock

- Chain chip conveyor

- Automatic lubrication system

- Standard tool kit

- CE certificate

- Instructions for use in English

Optional equipment (additionally paid):

- Tailstock with screw drive

- Through-hole hydraulic chuck and cylinder

- Device for pre-setting tools

- Air conditioner

- Oil mist separator

- Bar feeder

- Automatic doors

- German hydraulic rest

| Technical data | Unit | Value |

|---|---|---|

| Turning diameter over bed | [mm] | 280 |

| X-axis travel range | [mm] | 170 |

| Z axis travel range | [mm] | 300 |

| Rotation speed | [rpm/min] | 5000 |

| Spindle tip | [-] | A2-5 / Opcja: A2-6 |

| Spindle flight | [mm] | F63 |

| X / Z accelerated feed | [m/min] | 30/30 |

| Tailstock sleeve diameter | [mm] | 70 |

| Main spindle motor | [kW] | 7,5/11 |

| Max. rotation diameter over bed | [mm] | 480 |

| Max. turning diameter (shaft) | [mm] | 280 |

| Max. turning diameter (disc) | [mm] | 300 |

| Max. turn length | [mm] | 300 |

| Guide type | [-] | Prowadnica liniowa |

| Handle size | [*] | 6 |

| Max. rod capacity (equipped with through-hole hydraulic chuck) | [mm] | F45 (F47) |

| Tower type and number of tools | [-] | 12-pozycyjna wieża z oprzyrządowaniem na żywo |

| Tool shank size | [mm] | 20x20 |

| Indexing time (adjacent/farthest) | [s] | 0,31 / 0,76 |

| Tailstock step | [mm] | 120 |

| Positioning accuracy of the X/Z axis (C, Y) | [mm] | 0,005/0,005 C:44” |

| Repeatability accuracy of the X/Z axis (C, Y) | [mm] | 0,003/0,003 C:18” |

| External dimensions L x W x H | [mm] | 2360 x 1720 x 1835 |

| Net weight | [kg] | 4800 |

Recommended

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.