CNC Lathes

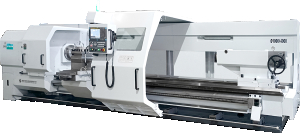

DMTG CKE6180Z x 1500 CNC LATHE

Priced individually

No rating

12 months of warranty

Contact with a trader:

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

The DMTG CKE6180Z x 1500 cnc lathe is a flat bed machine controlled in both the longitudinal (Z axis) and transverse (X axis) directions. It is able to automatically perform machining processes of various details such as shafts and discs, including internal and external cylindrical surfaces, conical surfaces, circular arc surfaces, end faces, grooves, chamfers, etc. In addition, it can also perform turning operations for metric elements such as straight threads, face threads, straight inch threads and tapered threads. The lathe is suitable for the production of a variety of products in medium and small batches, perfectly coping with the machining of complex and precise parts.

The DMTG CKE6180Z x 1500 cnc lathe is a flat bed machine controlled in both the longitudinal (Z axis) and transverse (X axis) directions. It is able to automatically perform machining processes of various details such as shafts and discs, including internal and external cylindrical surfaces, conical surfaces, circular arc surfaces, end faces, grooves, chamfers, etc. In addition, it can also perform turning operations for metric elements such as straight threads, face threads, straight inch threads and tapered threads. The lathe is suitable for the production of a variety of products in medium and small batches, perfectly coping with the machining of complex and precise parts.

Machine Features:

- The machine was designed using finite element analysis, which theoretically analyzes and calculates the overall layout and key structures of the machine. This results in high stiffness, minimal thermal distortion, low spindle temperature rise, low vibration and the ability to withstand high cutting torque. These features enable the machine to adapt to cutting with heavy loads and achieve a globally advanced design concept.

- The key elements of the machine, such as the CNC system and spindle bearings, come from renowned domestic and foreign manufacturers, which ensures high reliability of the machine.

- Advanced design combined with comprehensive process measures ensure that the machine has high machining accuracy and long-term precision. The consistency of the workpieces is excellent, achieving stable precision levels ranging from IT6 to IT7, with surface roughness up to Ra1.6 μm.

- Key parts of the machine, including the bed, headstock housing, saddle and tailstock, are machined using advanced equipment. The use of top-class processing equipment guarantees high precision of machine elements, which is necessary to ensure various technical parameters of the machine.

- The machine uses an integrated mechanical and electrical design, characterized by a compact and rational layout that ensures user-friendly and pleasant operation, as well as ease of maintenance.

- The design of the machine is modular, which allows for various configurations depending on the user's requirements (e.g. different tool heads, tailstocks, systems, etc.).

Standard equipment:

- 3-jaw manual chuck

- Hand horse

- Fanuc 0i-TF (5) Plus system

- 4-position knife holder

- Manual speed change

- CE certificate

- User manual in English

Optional equipment (additionally paid):

- 4-jaw manual chuck

- 6/8 tool head

- Hydraulic tailstock

- Movable rest

- Eyepiece

- GKS system

- Automatic speed change

- Hydraulic chuck

- Siemens system

| Technical data | Unit | Value |

|---|---|---|

| Turning diameter over bed | [mm] | 800 |

| Turning diameter over slide | [mm] | 490 |

| Workpiece length | [mm] | 1500 |

| X-axis travel range | [mm] | 400 |

| Z axis travel range | [mm] | 1250 |

| Rotation speed | [rpm/min] | 1000 |

| Spindle tip | [-] | C11 |

| Spindle flight | [mm] | 100 |

| X / Z accelerated feed | [m/min] | 4/7,5 |

| Tailstock sleeve diameter | [mm] | 100 |

| Tailstock taper | [-] | ST6 |

| Main spindle motor | [kW] | 11 (silnik napędzany falownikiem) |

| Handle size | [*] | 400 |

| Tool shank size | [mm] | 32 x 32 (32 X25 poziomo, 8 pozycji) |

| Tailstock step | [mm] | 240 |

| Positioning accuracy of the X/Z axis (C, Y) | [mm] | 0,026 |

| Repeatability accuracy of the X/Z axis (C, Y) | [mm] | 0,014 |

| External dimensions L x W x H | [mm] | 3905 x 2020 x 1805 |

| Net weight | [kg] | 5600 |

Recommended

CNC Lathes

Priced individually

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.