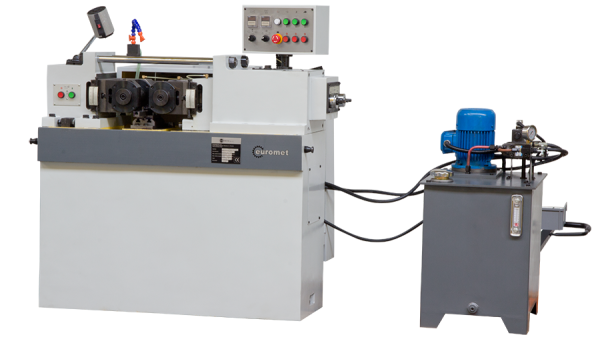

EUROMET TRM 28-16 ROLLING MACHINE FOR THREADS AND SPLINES

Krzysztof Penkowski

E-mail: krzysztof.penkowski@eurometal.com.pl

Telefon: 603 400 333

Thread rolling machines are efficient machines for chipless processing of threads, splines, etc. In two-roll machines, the rolls rotate in a synchronized motion in the same direction, burnishing the thread or spline on the cylindrical surface. Rolling threads or splines is a more efficient and faster method than cutting them.

Thread rolling machines are efficient machines for chipless processing of threads, splines, etc. In two-roll machines, the rolls rotate in a synchronized motion in the same direction, burnishing the thread or spline on the cylindrical surface. Rolling threads or splines is a more efficient and faster method than cutting them. Two-roll mills are used to make threads in solid materials, while three-roll mills are used to make threads on pipes. The TRM28-6.3A and TRM28-12.5 machines are blind machines and enable threading with the plunge method. The remaining two-roll machines are pass-through devices - they have tilting rolls - which allows making a thread longer than the width of the tools.

- Hydraulic unit

- User manual in English

- CE Declaration of Conformity

- Tool set for rolling threads, splines, etc.

| Technical data | Unit | Value |

|---|---|---|

| Maximum rolling force (end of threads) | [KN] | 150 |

| Maximum diameter of radial feed (end of threads) | [mm] | 80 |

| Maximum diameter of the axial feed (end of threads) | [mm] | 50 |

| Maximum pitch of radial feed (end of threads) | [mm] | 6 |

| Maximum axial stroke (end of threads) | [mm] | 4 |

| Outer die diameter | [mm] | 210 |

| Die width | [mm] | 140 |

| Die bore diameter | [mm] | 54 |

| Spindle axis distance | [mm] | 130 - 260 |

| Spindle speed | [rpm/min] | 20 - 80 |

| Spindle tilt angle | [°] | ±8 |

| Rolling - feed value (stepless) | [mm/s] | 5 |

| Rolling - shift / stroke | [mm] | maks. 20 |

| Rolling time | [s] | 0 – 60 |

| Total power | [kW] | 7,1 |

| Box dimensions (LxWxH) | [mm] | 1900x1800x1850 |

| Weight | [kg] | 3000 |

Recommended

Newsletter