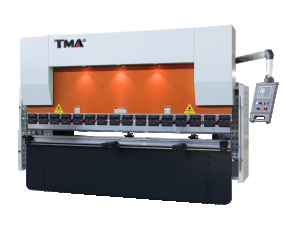

Hydraulic Press Brakes

TMA WC67K 130Tx4000 CNC press brake

Priced individually

No rating

12 months of warranty

Contact with a trader:

Krzysztof Penkowski

E-mail: krzysztof.penkowski@eurometal.com.pl

Telefon: 603 400 333

Krzysztof Penkowski

E-mail: krzysztof.penkowski@eurometal.com.pl

Telefon: 603 400 333

TMA WC67K 130Tx4000 CNC press brake is equipped with CNC table deflection compensation system for high quality upgrade, servo driven backgauge system for increased speed and control unit equipped with 3D graphics to simulate bending sequences and collision points, also has enhanced speed performance, stroke, clearance.

TMA WC67K 130Tx4000 CNC press brake is equipped with CNC table deflection compensation system for high quality upgrade, servo driven backgauge system for increased speed and control unit equipped with 3D graphics to simulate bending sequences and collision points, also has enhanced speed performance, stroke, clearance.

Main features:

The heat treatment of the machine frame, the verification of the rigidity optimization of the whole machine, and the use of hydraulic compensation structure together ensure the bending precision of the TMA series press brakes.

Standard mb8 2 axis backgauge system as for complex shape detail, 4 or 5 axis backgauge system and corresponding dies are available for your option.

Press brake using fully closed loop electro-hydraulic servo control technology, ram position signals can be fed back to the nc system by

Double-sided grilles, then the nc system regulates the size of the fuel tank by changing the size of the synchronous valve opening, thus controlling the slider (y1, y2) operating at the same frequency, maintaining the parallel state of the working table.

According to the sheet metal process status, the cnc system can automatically control the table deflection compensation value, resulting in the uniformity of the length and angle of all workpieces.

The use of hydraulic deflection compensation gives access to uniform full-length details. The hydraulic deflection compensation consists of a set of oil cylinders in the working table, which can make the table make relative movement and form a perfect convex curve, ensuring the relative position relationship with the slider remain unchanged. Compensation values depend on the thickness of the sheet metal and the properties of the material being cut.

Standard configuration:

- Cybelec CT8 or ESA S630 CNC control in English

- Positioning accuracy in the Y1 and Y2 axes 0.01 mm

- The machine has a 4+1 axis (Y1,Y2,X,R+V) / 40T and 50T models do not have a V axis

- The servo motors drive the X-axis (X-axis, R 0.01mm), the stop finger can be easily moved along the cylindrical guide.

- Maintained accuracy between Hiwin ball screw and linear guide within 0.01mm

- The front support can be adjusted along the linear guide towards the work table

- Rexroth electro-hydraulic fully closed-loop servo controls the system synchronously

- EMB oil pipe fittings

- Schneider Electrics components used

- Hydraulic and electrical overload protection

- Mechanical quick crimping dies on the slider. There are easily replaceable double v-groove dies on the table.

Optional equipment (extra charge):

- Controls: ESA, CYBELEC, DELEM

- DSP or Akas laser protection

- Cooler

- LNTECH rear curtain

| Technical data | Unit | Value |

|---|---|---|

| Pressure | [t] | 130 |

| Bending length | [mm] | 4000 |

| Distance between columns | [mm] | 3200 |

| Stroke | [mm] | 200 |

| Ground clearance | [mm] | 435 |

| Recess depth | [mm] | 400 |

| Travel Speed | [mm/s] | 150 |

| Return Speed | [mm/s] | 135 |

| Matrix setting height | [mm] | 530 |

| Engine power | [kW] | 11 |

| Oil tank size | [l] | 300 |

| Working speed | [mm/s] | 10 |

| Dimensions (LxWxH) | [mm] | 4300x1650x2660 |

| Weight | [kg] | 10000 |

Recommended

Hydraulic Press Brakes

76 512,15 zł

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.