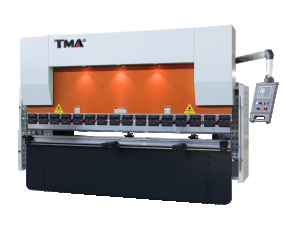

Hydraulic Press Brakes

NC press brake TMA WC67Y 250Tx3200

281 153,60 zł net

No rating

12 months of warranty

Contact with a trader:

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

The NC 250Tx3200 series WC67Y press brake reacts in the most appropriate and responsive way to mechanical stimuli, thus guaranteeing a stable structure, resulting in greater bending precision. This feature is enhanced by the manual deflection compensation system. It is also worth mentioning the possibility of adding options and updating the configuration at a later stage. Built with high-quality parts, it offers high reliability, Y-axis torsion bar synchronization technology with high travel, work and return speeds.

The NC 250Tx3200 series WC67Y press brake reacts in the most appropriate and responsive way to mechanical stimuli, thus guaranteeing a stable structure, resulting in greater bending precision. This feature is enhanced by the manual deflection compensation system. It is also worth mentioning the possibility of adding options and updating the configuration at a later stage. Built with high-quality parts, it offers high reliability, Y-axis torsion bar synchronization technology with high travel, work and return speeds.

MAIN FEATURES:

- Integrated hydraulic system used, more reliable and easy to maintain. and the hydraulic system of the German company Bosch-Rexroth

- The mechanical synchronous mechanism and complex compensation are designed to increase the precision of the workpieces

- The stroke and distance of the backgauge are controlled by the motor. They are easily set manually, the values are displayed digitally

- Inch single continuous working mode designed for the machine, and the retraction and holding time can be controlled by time relays

- Safety fence and electric protection have been adopted to ensure work safety

ESTUN E21S CONTROL SYSTEM

- Monochrome LCD panel

- Freely programmable integration factor

- Automatic positioning control

- Spindle stock offset

- Internal timer

- Bend counter

- Back gauge position display, resolution 0.01mm

Standard configuration:

- Front supports on T-slots for comfortable sliding left and right

- Controls: ESTUN E21

- Pump: USA SUNNY

- Motor: Shandong Longtou/SIEMENS

- Double ground shaft

- Foot pedal from the Korean brand KACON

- Fixing

- German EMB coupling

- Hydraulic system: BOSCH-REXROTH

Optional equipment (extra charge):

- Motor driven arrow deflection compensation

- Mechanical arrow deflection compensation

- Double V-groove tools

- Italian MAPPER HT072

- Light curtains

- Taiwan HIWIN linear guides and ball screws

- Italian DSP laser protection

| Technical data | Unit | Value |

|---|---|---|

| Pressure | [t] | 250 |

| Bending length | [mm] | 3200 |

| Distance between columns | [mm] | 2600 |

| Stroke | [mm] | 250 |

| Ground clearance | [mm] | 480 |

| Recess depth | [mm] | 350 |

| Travel Speed | [mm/s] | 70 |

| Return Speed | [mm/s] | 60 |

| Engine power | [kW] | 22 |

| Oil tank size | [l] | 280 |

| Working speed | [mm/s] | 7,5 |

| Dimensions (LxWxH) | [mm] | 3100x1800x2900 |

| Weight | [kg] | 14000 |

Recommended

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.