Machine categories

Tube laser cutting machines

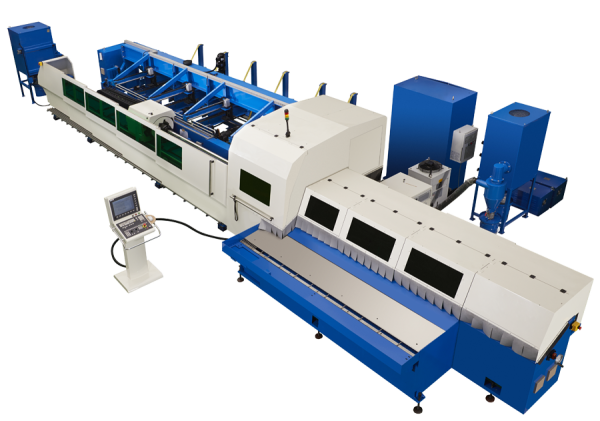

SOCO SLT-152 FIBER pipe laser cutting machine

Priced individually

No rating

12 months of warranty

Contact with a trader:

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

SOCO SLT-152 FIBER pipe laser cutting machine - automatic SOCO line for CO2 laser cutting of pipes and profiles with a maximum cutting diameter of up to 152 mm and a wall thickness of 6 mm for black steel. Thanks to the automation of the production process, it is possible to cut and punch complex shapes using one device while reducing the amount of waste generated.

SOCO SLT-152 FIBER pipe laser cutting machine - automatic SOCO line for CO2 laser cutting of pipes and profiles with a maximum cutting diameter of up to 152 mm and a wall thickness of 6 mm for black steel. Thanks to the automation of the production process, it is possible to cut and punch complex shapes using one device while reducing the amount of waste generated.

The machine has a 6.5 m automatic feeder with positioning of the distance of the material from the laser head nozzle, thus facilitating cutting of the shape entered into the SOCO CAD control system, as well as automatic unloading of the finished element.

Machine features:

- Automatic laser cutting system for processing pipes, square pipes, rectangular pipes and profiles

- Max pipe diameter 152 mm wall thickness 6 mm (black steel)

- The machine uses a fiber laser source, so the labor and adjustment costs are minimal

- The machine enables cutting of ordinary quality steel, stainless steel, aluminum and other difficult-to-cut materials.

- Typical operations that can be performed:

- Cutting

- Cutting at an angle

- Punching

- Making holes

- The machine can comprehensively produce parts with very complex shapes.

- Easy import of 2D/3D CAD files into the machine program and creation of machining programs

- It can replace other conventional devices for making complex details.

- The machine is equipped with safety covers in accordance with the Machinery Directive and the machine is CE marked

Standard equipment:

- SOCO SLT 152 machine base equipped with 5 axes controlled by servomotors

- Feed system with 6500 mm table and rotating head

- 1000 W laser resonator

- The cutting head is equipped with a quickly replaceable lens system and a capacitive head height adjustment sensor

- High pressure gas valve

- Magazine for feeding pipes 6500 mm

- Material unloading system with a 2000 table

- Air conditioning system

- Cutting head cooling system

- Gas absorption system

- Connectors (hoses) for cutting gases

- Connectors (hoses) for cooling gases

- Control system

- One SOCO-CAD software license (can be installed on an additional computer or client computer)

- One industrial copier, equipped with a CF / USB / Ethernet reader

- Internet connection with IRMS

- One set of lenses

- Jaws for the feed carriage (automatic centering) x 2 (up to 20 – 80 mm and 75 – 150 mm)

- Rollers for the rotation system (automatic centering) x 2 (up to 20 – 80 mm and 75 – 150 mm)

- Consumables:

- a) Nozzles: 1.2 x 2, 1.5 x 2, 2.0 x 2

- b) Optics covers x 5

Optional equipment (additionally paid):

- 2000 W laser source

- Unloading table 3000 mm

- Seam detection

- Nozzles

- Glass optics covers

- Lenses

| Technical data | Unit | Value |

|---|---|---|

| Possibility to cut the pipe | [mm] | 20 - 20 |

| The possibility of cutting a square profile | [mm] | 120 - 120 |

| Possibility to cut a rectangular profile | [mm] | 20 - 20 |

| Material length | [mm] | 2000 - 6500 |

| Workpiece length | [mm] | 2000 (opcja 3000) |

| Workpiece weight on the machine bed | [kg] | 120 |

| Bundle weight | [kg] | 4000 |

| X axis speed | [m/min] | 100 |

| Y axis speed | [m/min] | 25 |

| Z axis speed | [m/min] | 30 |

| A axis speed | [°/s] | 720 |

| Positioning accuracy | [mm] | +/- 0.2 |

| Dispersion accuracy | [mm] | +/- 0.2 |

| Wall thickness of the material to be cut | [mm] | 0,6 - 6,4 |

| Resonator power | [kW] | 2 (opcja 2,5) |

| Feeder weight | [kg] | 5000 |

| Weight of the base of the cutter | [kg] | 3300 |

| Machine base weight | [kg] | 4700 |

| Weight of workpiece reception | [kg] | 3000 |

| Weight of the cooling system | [kg] | 1000 |

| Gas extractor weight | [kg] | 800 |

| Dimensions (LxWxH) | [mm] | 12950x4673x2190 |

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.