Pipe and section bending machines - with mandrel

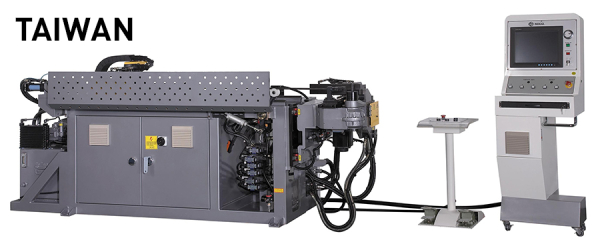

SOCO V SB-20x4A-3SV electric CNC pipe bender

292 000,00 zł net

No rating

12 months of warranty

Contact with a trader:

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

SOCO A series hydraulic bending machines equipped with CNC control and servo motor drives for 3-4 axes, with one, two or three stacks of dies. The unique DGT bending head drive system, using a gear transmission and a servo motor drive, ensures even greater bending efficiency and stability. Operation is simple and intuitive, and the bending accuracy is very high.

Quantity

Add to cart

SOCO A series hydraulic bending machines equipped with CNC control and servo motor drives for 3-4 axes, with one, two or three stacks of dies. The unique DGT bending head drive system, using a gear transmission and a servo motor drive, ensures even greater bending efficiency and stability. Operation is simple and intuitive, and the bending accuracy is very high.

Main features of the device:

- Unique head design – DGT system

- CNC controller with touch screen

- The tube carriage is fed using a toothed rack and a servomotor

- Possibility to mount multiple stacks of dies and rolls – for large radii

- Programmable force of the supporting device for 1D bending

- Programmable arc length for large radii

- Material elasticity compensation for roll bending

- Compensation for die bending

- Entering data in the YBC and XYZ system

- Possibility to convert data from XYZ to YBC

- The bending arm is equipped with an additional actuator supporting the bending process - booster

- Electrical system equipped with a cooling system

- Automatic lubrication system for the mandrel increases its life as well as the quality and accuracy of bending

- Smoothing die support with lubrication

- The control panel is placed on a movable base, enabling the most favorable positioning for the operator

Main control features:

- Operating system running under Windows

- Mitsubishi servomotors that feed and rotate the pipe

- Possibility to save programs on hard disk or FDD

- Ability to store 30,000 files (up to 110 bends per pipe)

- Possibility of 3D visualization of the bent model

- Possibility to convert from YBC to XYZ and vice versa

- Possibility of freely rotating the element on the display

Standard equipment:

- Early pin retraction system

- Automatic pin lubrication system

- Central lubrication system

- Bending die support system

- Portable control panel

- User manual in English

- CE Declaration of Conformity

| Technical data | Unit | Value |

|---|---|---|

| Diameter of the bent pipe (steel) | [mm] | 1.2 - 20 |

| Diameter of the bent pipe (stainless steel) | [mm] | 1.2 - 16 |

| Tube length with mandrel | [mm] | 2070 |

| Bending radius | [mm] | 80 |

| Bending angle | [°] | 190 |

| Bending accuracy | [°] | +/- 0,1 |

| The accuracy of the positioning movements | [°] | +/- 0,1 |

| Accuracy of the feed | [°] | +/- 0,1 |

| Die bending radius - profile | [mm] | 2,5D – 4D |

| Die bending radius - pipe | [mm] | 1,5D – 4D |

| Bending radius on rollers - pipe | [mm] | 6D - ∞ |

| Roller bending radius - profile | [mm] | 8D - ∞ |

| 1D bending | [-] | Tak |

| Die radius difference | [mm] | 80 |

| Dimensions | [mm] | 2780x 950x 1120 |

| Weight | [kg] | 1500 |

Recommended

Pipe and section bending machines - with mandrel

Priced individually

No rating

Pipe and section bending machines - with mandrel

766 649,90 zł

No rating

Pipe and section bending machines - with mandrel

Priced individually

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.