Pipe and section bending machines - with mandrel

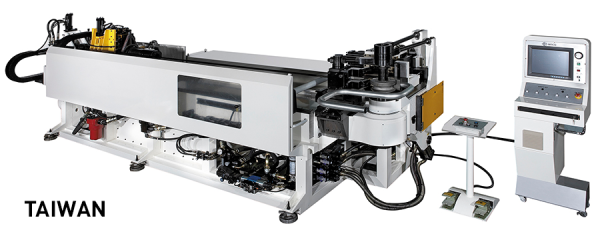

CNC pipe bender SOCO SB-168x5B-1S (2S)

Priced individually

No rating

12 months of warranty

Contact with a trader:

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

SOCO 5B series hydraulic bending machines equipped with CNC control and servo motor drives for 5 axes. Operation is simple and intuitive, and the bending accuracy is very high. These bending machines are widely used in the automotive and shipbuilding industries.

SOCO 5B series hydraulic bending machines equipped with CNC control and servo motor drives for 5 axes. Operation is simple and intuitive, and the bending accuracy is very high. These bending machines are widely used in the automotive and shipbuilding industries.

The 5B series are devices with 5 CNC-controlled axes with one or two die stacks. In the case of a machine with 2 die levels, changing the die is carried out by lifting the pipe carriage, the mandrel mounting and the pipe itself. In A, V, MR and MRV series machines, this is achieved by changing the height of the bending head based on guides and moved by servo motors.

Main features of the device:

- CNC controller with touch screen

- 5 individually programmable axes (feed - Y, rotation - B, bending - C, movements in the horizontal plane - X1 and X2, pressure matrix support - V1)

- Possibility to program two speeds of pin retraction

- Individually selected pressure die support pressure for each set of tools

- Entering data in the YBC and XYZ system

- Possibility to convert data from XYZ to YBC

- Feed and rotation performed using servo motors - this solution is characterized by high reliability, precision and efficiency

- Hydraulic bending arm equipped with an additional actuator supporting the bending process

- Electrical system equipped with a cooling system

- Automatic lubrication system for the mandrel increases its life as well as the quality and accuracy of bending

- Automatic compensation of material elasticity

- Smoothing die support

- Spindle retraction programming function

- The control panel is placed on a movable base, enabling the most favorable positioning for the operator

Main control features:

- Operating system running under Windows

- Mitsubishi servomotors that feed and rotate the pipe

- Possibility to save programs on hard disk or FDD

- Ability to store 30,000 files (up to 110 bends per pipe)

- Possibility of 3D visualization of the bent model

- Possibility to convert from YBC to XYZ and vice versa

- Possibility of freely rotating the element on the display

- Possibility to download monthly production

Standard equipment:

- Early pin retraction system

- Automatic pin lubrication system

- Central lubrication system

- Bending die support system

- Portable control panel

- User manual in English

- CE Declaration of Conformity

| Technical data | Unit | Value |

|---|---|---|

| Diameter of the bent pipe (steel) | [mm] | 6.8 - 168 |

| Diameter of the bent pipe (stainless steel) | [mm] | 4.3 - 168 |

| Bending radius | [mm] | 600 |

| The length of the pin | [mm] | 7000 |

| Bending angle | [°] | 190 |

| Bending speed | [°/sec] | 10 |

| Bending accuracy | [°] | +/- 0,1 |

| The accuracy of the positioning movements | [°] | +/- 0,1 |

| Accuracy of the feed | [°] | +/- 0,1 |

| The difference between the radiuses | [mm] | 160 |

| Dimensions | [mm] | 9500x2880x2600 |

| Weight | [kg] | 17000 |

Recommended

Pipe and section bending machines - with mandrel

Priced individually

No rating

Pipe and section bending machines - with mandrel

390 807,90 zł

No rating

Pipe and section bending machines - with mandrel

1 209 945,65 zł

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.