New solutions from IMET for band and circular saws

SAWprogram is an easy-to-use and intuitive software that allows you to create cutting programs and monitor the machine operation process on each computer in the company. The software is available for free and can be downloaded (after registration).

SAWprogram and SAWfactory are advanced and easy-to-use tools developed by the research and development department to optimize and improve the automation of our clients' work.

Software and web application

SAWprogram is an easy-to-use and intuitive software that allows you to create cutting programs and monitor the machine operation process on each computer in the company. The software is available for free and can be downloaded (after registration) by clicking on this link.

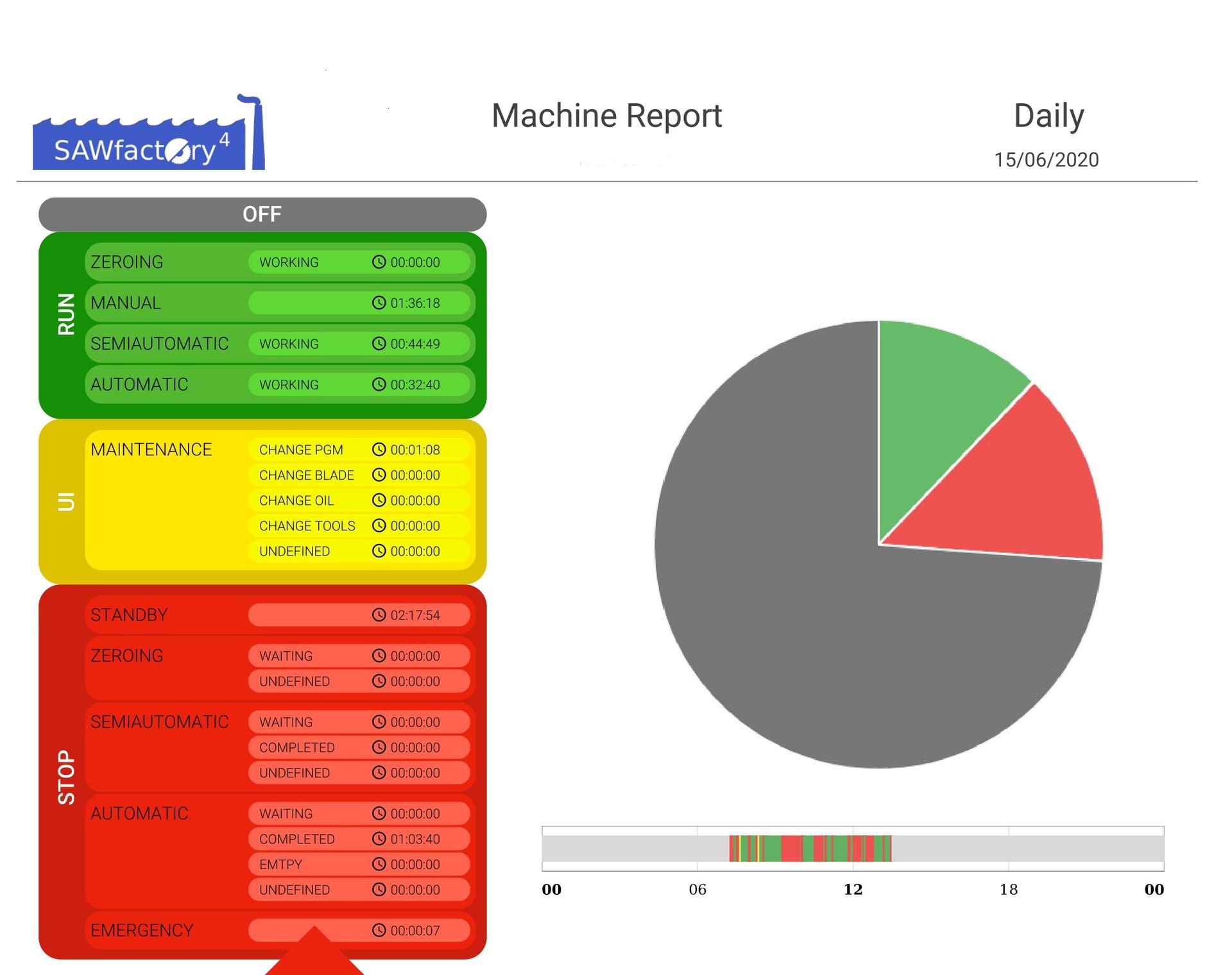

By adding Imet Industry 4.0 Ready - SAWFACTORY to your band saw and circular saw (which includes the installation of a data logger with "SafeConnect" technology), you will have access to the SAWfactory web application from any device, allowing you to fully remotely manage cutting processes, export statistics and reports with access to the Imet teleservice for remote technical support.

SAWprogram

Teleservice

SAWprogram

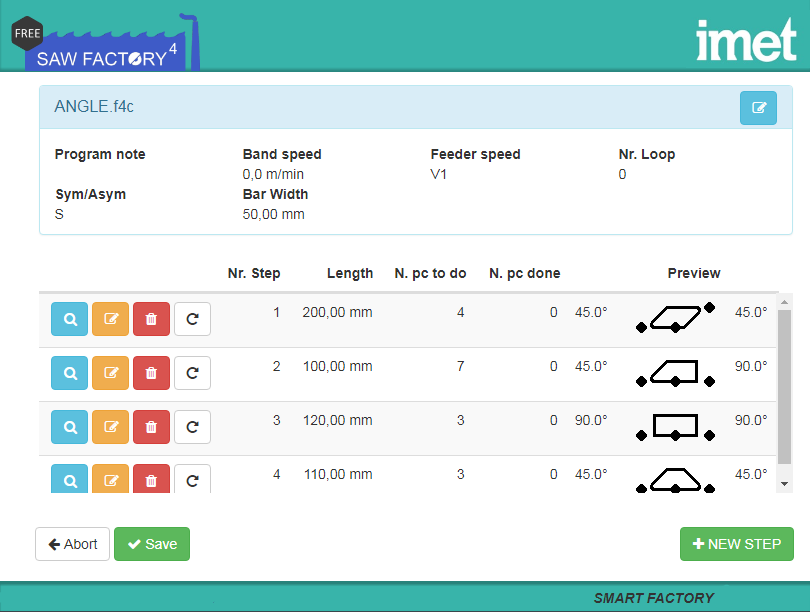

SAWprogram (available for free at this linkiem) is a software compatible with Windows 10 and subsequent versions that allows you to create cutting programs on a company PC, adding steps and parameters to optimize the process of band and circular saws. You can import CSV, DSTV, and DSTV + files into the software, and import and convert Logibarre files (used for nesting bars) to machine compatible files. After creating the program, the user can easily import it directly to the machine in the factory using a USB key or the internal company network.

Main features of the SAW program:

- Create and import a program and cutting parameters

- Modifying the cutting program

- Compatibility, import and conversion of DSTV and DSTV + files

- Import and convert Logibarre files (for nesting)

- Import CSV files

- Transferring the cutting program to the machine using a USB key

- Compatible with Windows 10 and subsequent versions

Teleservice

The Industry 4.0 Ready option includes the ECOhost Amsterdam data logger (option available for all automatic band and circular saws) which uses SafeConnect technology to guarantee the highest level of protection for the corporate network. The data logger provides access to teleservice and remote technical support that can monitor machine operation to control machine settings and status.

Main features of SAWfactory:

- Live machine health monitoring via web app

- Live cutting program monitoring via web application

- Blade life status via web application

- Export of cutting history via web application

- Export of the log file to the work history (alarms, settings) in the web application

- Daily machine performance reports with statistics and advanced data

- Teleservice: machine status, information about the software version, reading machine settings, remote modification of some parameters as well as machine control and management

- Transfer of the program to a selected machine with an internet connection

- All the main functions of the SAW program

Which Imet band and circular saws support SAW and SAWfactory?

SAWprogram and SAWfactory are fully compatible with all Imet automatic band and circular saws that use an innovative and intuitive touchscreen (7 "or 10") with an easy and responsive user interface designed to optimize the work of professionals; all these machines can connect to Industry 4.0 solution both via network connection and USB dongle:

CUBO SERIES

- CUBO 300 NC FLAT

- CUBO 350 NC FLAT

- CUBO 400 NC FLAT

- CUBO 300 NC BOX

- CUBO 350 NC BOX

- CUBO 400 NC BOX

AUTOMATIC CIRCULAR SAWS

- SIRIO 370 AF-NC

- VELOX 350 AF-NC

- VEOX 350 AF-ENC

AUTOMATIC MAXI LINE BAND SAWS

- H 601 NC

- H 700 - 800 - 1200 NC F1500-3000

- XSMART3

- KTECH 502 - 652 F2000

- KTECH 802 - 1202 F3000-6000

- XT4 - XT5 - XT6

Date of publication: 27.09.2021